Automated Order Fulfillment: How Modern Logistics Powers Faster, Smarter Retail

Automated order fulfillment uses AI, robotics, and integrated systems to speed up processing, cut errors, and improve scalability. Core technologies include OMS, WMS, robotics, and shipping software working together to create a seamless fulfillment ecosystem.

Start small with automation, such as order routing, and expand by integrating systems, defining rules, and optimizing with data.

Automation solves key logistics pressures like labor shortages, omnichannel complexity, and rising customer delivery expectations. The future of retail lies in predictive, adaptive logistics with AI-driven forecasting, robotic micro-fulfillment centers, and autonomous last-mile delivery.

The retail landscape today demands speed, precision, and scalability. Shoppers expect their orders to be accurate, fast, and flexible—whether they buy online, in-store, or through social platforms.

By leveraging AI-driven software, connected systems, and smart logistics, you can process orders without manual intervention—from order capture to pickup, packing, and shipping. This results in faster service, fewer errors, and greater efficiency at scale.

Modern consumers define fast shipping as delivery in just over three days, with 95% to 97% agreeing that same-day or next-day delivery is acceptable. This reflects shoppers’ growing expectations and the necessity for a scalable, efficient, and automated fulfillment business model.

In this article, we’ll review what automated fulfillment means, why it’s essential, the key benefits it delivers, the tech that powers it, and how you can implement automation to future-proof your business operations.

What is automated order fulfillment?

Automated order fulfillment involves using technology—software, systems, algorithms, and artificial intelligence—to handle the entire order process without manual intervention. This includes everything from order capture to picking, packing, and shipping, all orchestrated seamlessly.

It typically covers six core stages:

- Order ingestion: Capturing orders from multiple channels, such as e-commerce websites, marketplaces, social platforms, and physical stores, into a central system.

- Inventory validation: Confirming available stock (owned and 3P), preventing oversells across locations.

- Fulfillment routing and allocation: AI-driven decision-making routes each order to the optimal fulfillment source—warehouse, store, or 3PL.

- Picking, packing, and labelling: Guided workflows or robotics fully automate item selection, packaging, and label generation.

- Shipping integration: The system auto-generates carrier labels, tracks shipments, and pushes alerts back to the order platform.

- Real-time updates and exception handling: From inventory updates to shipping delays or address errors—the system proactively identifies and resolves issues.

Combining these integrated steps reduces friction, boosts speed, and improves consistency, which is critical as your order intake volume scales.

Why is automation essential for modern logistics?

U.S. freight operators say the biggest hurdle today is labor shortage—25% of firms report staffing gaps as their top concern—and they’re operating amid surging demand. Automation is no longer operational; it’s the key to plugging efficiency gaps and scaling sustainability.

Here are some key logistics pressures that automation can help you solve:

- Labor shortage and rising wage costs: A shrinking workforce and mounting wage bills are squeezing margins; automation can help you fill critical gaps without risky cost hikes.

- Customer delivery expectations: Shoppers expect near-instant dispatch and accurate ETAs; automated workflows can reduce cycle times and cut errors.

- Multinode complexity: Orchestrating stock and service levels across every node—warehouses, stores, and 3PLs—requires rules-based routing rather than spreadsheets.

- Visibility and error reduction: Manual processes are error-prone, but automation can deliver consistent accuracy, complete visibility, and operational peace of mind.

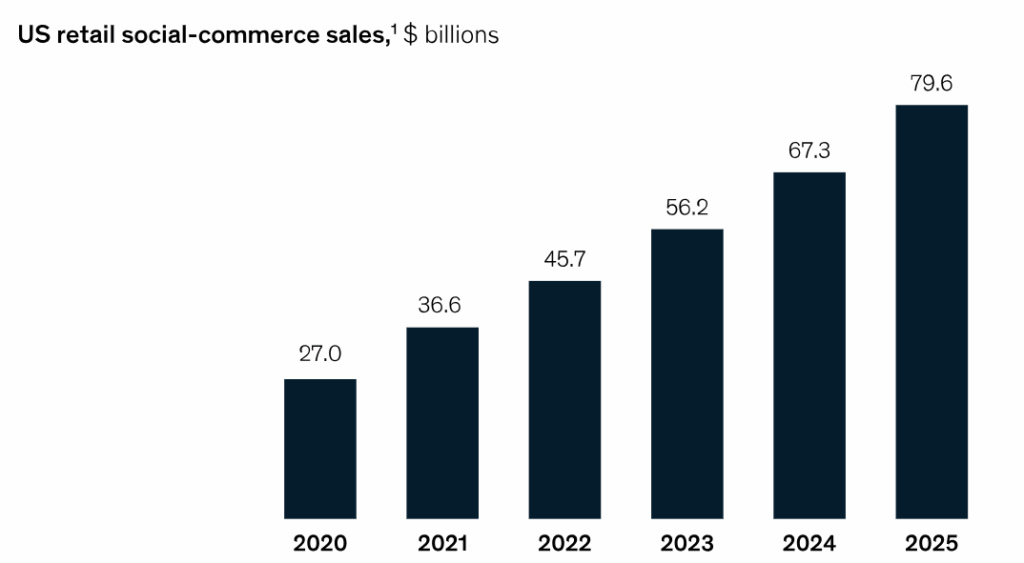

- Surging omnichannel order volumes: Social commerce alone is set to approach $80 billion in the U.S. by the end of 2025, signalling heavier order volumes across channels that manual workflows can’t keep up with.

Source: McKinsey

Automation can integrate foundational capability for modern logistics—powering speed, precision, and cost-efficiency that your business needs for scalable growth.

Benefits of automated order fulfillment

An automated order fulfillment software can give you a competitive edge with various advantages, such as:

- Faster processing times: Amazon’s robots have slashed order cycle times by 30% while boosting accuracy to 99.7%, proving that automation can make fulfillment faster and more reliable.

- Reduce manual errors: Automated picking systems can cut picking mistakes by up to 70%, resulting in fewer returns, less rework, and happier customers.

- Scalability during peaks: Whether it’s holiday surges or flash sales, automation flexes on demand, handling volume spikes without the need for additional staff.

- Improved inventory accuracy: Store inventory accuracy typically lags at 70–90%, while distribution centers maintain accuracy above 99.5%. Automation can help you close such gaps by providing real-time synchronization.

- Lower operational costs: Automation can shrink overloads and protect margins by reducing reliance on manual labor and streamlining packing/shipping workflows.

- Enhanced customer experience: Faster and more accurate delivery makes your customer happy and helps your brand gain loyalty.

What are the key technologies powering automation in fulfillment?

Modern, automated fulfillment relies on a high-powered toolkit—each layer working in sync to streamline operations end-to-end.

- Order Management Systems (OMS)

- Centralizes order data across e-commerce, marketplaces, and physical stores, enabling a unified view of demand.

- Automates routing logic using location, inventory, or cost-based rules.

- Supports split shipments and fallback paths when stock runs low at primary locations.

- Warehouse Management Systems (WMS)

- Tracks inventory location and movement, offering granular visibility.

- Manages tasks like picking, replenishment, and workflow orchestration.

- Supports barcode scanning and bin optimization, reducing manual scanning errors.

- Robotics and automation hardware

- Autonomous Mobile Robots (AMRs) can autonomously align picking workflows with minimal human oversight.

- Conveyors and robotic picking systems speed up goods-to-person workflows.

- Sortation and packing machines automate order consolidation into shipment-ready parcels.

- Shipping software and 3PL integrations

- Automates carrier matching, label generation, and tracking updates so your shipments go out faster and more accurately.

- Provides real-time delivery updates to customers, reducing the WISMO (Where Is My Order?) friction.

Each tool is powerful on its own, but when combined, they can transform your business operations and workflows. For instance, OMS combined with WMS can deliver:

- One unified platform with real-time inventory, order status, and allocation. No system silos.

- Better customer service by resolving the most frequent WISMO queries using live-order data.

- Smarter inventory forecasting and replenishment planning, reducing overstock and stockouts.

How to implement automated fulfillment workflows

Here are some tips on how you can automate your fulfillment workflow to ensure you don’t have to overhaul everything at once:

1. Audit your current fulfillment process

- Pinpoint bottlenecks and repetitive tasks that slow down your operations.

- Use metrics like pick-to-ship time and error rates to identify high-impact areas.

2. Integrate your systems

- Leverage integration features, such as the one we offer at fabric, to connect your e-commerce platforms with OMS, WMS, and shipping tools.

- Aligning these systems bridges data silos and unlocks real-time coordination across all channels.

3. Define automation rules

- Set logic based on location, stock levels, cost drivers, or delivery constraints.

- Include fallback and exception protocols to ensure robustness under changing conditions.

4. Train your team

- Engage your staff early with hands-on familiarization; studies show it reduces resistance to change by 50-70%.

- Ensure that your staff understands the why, and not just the what.

5. Monitor and optimize

- Use fulfillment data to refine rules and improve performance over time.

- Start small, for instance, automating order routing logic, and gradually build more complexity as each logic achieves its goal.

A phased approach can help you speed up the adoption process and deliver early value, reducing risk while building momentum. You can demonstrate ROI faster, adapt mid-course, and scale smartly without overwhelming your teams.

Future trends in fulfillment automation

The retail landscape is rapidly evolving, and the future of retail lies in automation that’s predictive, adaptive, and fully integrated across the entire fulfillment lifecycle. Here are some of the emerging trends in fulfillment automation that are shaping the future of retail:

- AI-powered demand forecasting and dynamic orchestration: AI and ML (Machine Learning) are becoming essential for predicting demand and triggering fulfillments even before orders are placed—helping you maintain optimal stock and reduce overstock or stockouts.

- Predictive inventory reallocation by proximity: Fulfillment systems will increasingly move inventory closer to where demand is expected—dynamically reallocating stock to reduce delivery times and cut transport costs.

- Robotic micro-fulfillment centers: Urban micro-fulfillment hubs powered by robotics position inventory close to consumers, speeding up fulfillment while reducing last-mile friction.

- Automated returns integration: Returns are becoming part of the same fulfillment layer, streamlining reverse logistics to be as fast and frictionless as outbound processing.

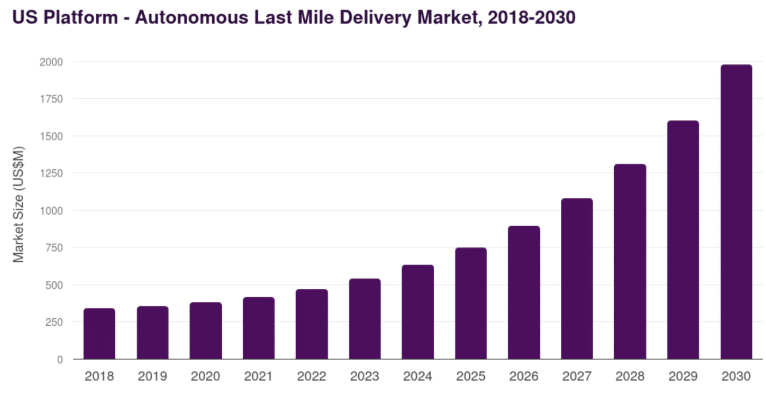

- Autonomous last-mile delivery: The U.S. autonomous delivery sector is on track to nearly triple from $623.3 million in 2024 to $1.98 billion by 2030, indicating that robots and drones will soon be standard logistics players.

Source: Grand View Research

Instead of simply automating tasks, the future of fulfillment is about building adaptive logistics—systems that anticipate demand, shift inventory proactively, and complete the order lifecycle with minimal friction.

The path to smarter, scalable fulfillment

The future of retail logistics is in automation. As customer expectations for speed and accuracy continue to rise, acting on adaptive automation will secure you a lasting competitive edge.

Automated order fulfillment is a strategic move that can help you expand across multiple channels while maintaining cost control, efficiency, and a consistently positive customer experience.

Are you ready to modernize your fulfillment operations? Contact us and explore how fabric OMS can help you power intelligent and smart automation across your order lifecycle and scale seamlessly.

Digital content editorial team @ fabric