How to Reduce Split Shipments and Cut Fulfillment Costs on Shopify

If you’re a high-growth brand scaling on Shopify, managing split shipments can become a growing challenge, one that quietly impacts margins and complicates fulfillment.

Even with Shopify’s robust tools, coordinating shipments across warehouses, retail stores, and dropship partners can lead to higher shipping costs, multiple delivery touchpoints, and a less-than-ideal customer experience. As your operations expand across more channels and geographies, the complexity and cost can escalate.

The good news? Shopify split shipping is a challenge you can solve. With the right order fulfillment strategy in place, you can streamline shipments, reduce costs, and deliver a better customer experience, without any custom code.

Let’s explore how.

Why Shopify split shipping happens

Shopify’s native capabilities work well for straightforward fulfillment needs. But once your business starts operating across multiple warehouses, many stores, and new selling channels, you’re more likely to run into scenarios where a single order gets split into multiple shipments. This typically happens when:

- Inventory for a single order isn’t available in one location

- Order fulfillment logic isn’t optimized for margin or efficiency

- The system lacks a centralized source of inventory truth

In these cases, you may fulfill parts of the order from different locations, charging shipping fees multiple times in the process. That means higher costs for you and your customers.

If you’re not actively managing this, you’re likely losing margin and loyalty on every multi-item order.

How split shipments impact your bottom line

Split shipments don’t just impact operational efficiency. They directly affect profitability and customer satisfaction:

- Higher fulfillment costs: Shipping from multiple locations increases transportation, packaging, and handling expenses.

- Duplicate shipping fees: Shopify can charge shipping fees per fulfillment location, leading to double (or even triple) charges for customers.

- Poor customer experience: Receiving multiple packages at different times with separate tracking numbers can feel disjointed and inconvenient.

- Environmental impact: More shipments = more trucks on the road = a larger carbon footprint.

If you’re looking to provide the best customer experience while preserving margin, split shipment reduction should be a top priority.

The smart way to avoid unnecessary split shipments

Growing brands that use Shopify for e-commerce are solving split shipping challenges by turning to purpose-built order management systems (OMS) that offer:

1. Smart order routing (without code)

Shopify’s native fulfillment logic has limitations when it comes to choosing the best fulfillment node. A modern OMS—like fabric OMS—uses configurable order logic to determine the most efficient and cost-effective fulfillment source for every order.

Orders can be routed based on:

- Inventory availability

- Proximity to the customer

- Fulfillment cost

- SLA commitments

- Safety stock levels

- Location capacity

This means fewer split shipments, lower costs, and better delivery speed, all without writing a single line of code.

2. Unified inventory across all channels

One major reason for split shipments is fragmented inventory. Shopify instances often “tie” inventory to a specific storefront or location, requiring manual allocation.

With fabric, inventory is automatically synced across your Shopify storefronts, warehouses, and partners. When a product is purchased, inventory updates in real-time, helping prevent overselling and ensuring fulfillment logic has the most accurate data.

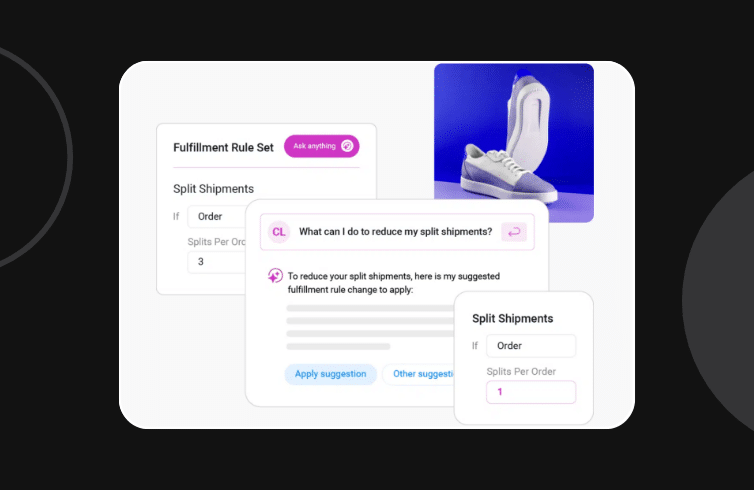

3. Prevention of duplicate shipping charges

Some merchants get creative with custom workarounds to prevent double charging for shipping, but it’s time-consuming and fragile.

fabric handles this out of the box, ensuring your customers don’t get hit with multiple shipping fees when orders are split. This keeps your checkout fair and frustration-free.

Example: Scaling smarter with smart fulfillment logic

Let’s say you receive an order for three items:

- Item A is in stock at your West Coast warehouse

- Item B is in stock at both East and West Coast warehouses

- Item C is only available via a dropship partner

A traditional system might split this order into three separate shipments, each with its own shipping fee.

fabric’s fulfillment logic evaluates configurable factors like proximity, cost, and availability, and intelligently consolidates where possible. For example, it might ship Items A and B together from the West Coast warehouse, and Item C from your dropshipper, cutting shipping charges and reducing delivery windows.

This flexibility gives you choice and control, while your customer gets a seamless experience.

From cost center to competitive advantage

Reducing Shopify split shipping is more than a cost-saving tactic. It’s a margin-expanding, loyalty-building, and growth-enabling move. And the best part? You don’t need to rebuild your tech stack to make it happen.

By extending Shopify with fabric, you can:

- Cut Shopify shipping costs with smart, automated fulfillment decisions

- Eliminate manual inventory allocations with real-time inventory visibility

- Reduce split shipments and preserve margin, without custom code

- Offer the best fulfillment services for Shopify customers across any channel

Ready to reduce split shipments?

If your team is navigating complex fulfillment scenarios or spending time managing split orders, it might be time to explore new ways to simplify and scale your operations.

fabric helps brands extend the power of Shopify—not replace it. We orchestrate inventory, orders, and fulfillment behind the scenes so you can focus on scaling without compromise.

Digital content editorial team @ fabric