E-commerce Order Fulfillment: Why Automation Is the Future

E-commerce fulfillment automation streamlines order processing, inventory syncing, smart routing, packing, shipping, and returns—solving the limitations of manual systems and siloed tools that can’t meet modern shopper expectations

Start with foundational automation like an OMS, routing rules, WMS/3PL connections, and predictive tools, then scale with advanced features including unified inventory, AI forecasting, and multi-channel integration

Automation directly improves customer satisfaction through fewer errors, faster deliveries, and smoother returns—building loyalty and protecting revenue at scale

E-commerce fulfillment is more complex than ever—shoppers these days expect fast, accurate, and transparent delivery, and manual processes aren’t sufficient. In the U.S., 74% of online shoppers say delivery speed influences where they buy, while 33% expect orders to be delivered within one or two days.

Source: Fit Small Business

If your team is scrambling to manage orders manually in spreadsheets or juggling inventory updates across systems, you’re not alone.

Automation is a modern solution that can help you scale operations, reduce errors, and meet growing customer expectations.

In this article, we’ll review how automation transforms the fulfillment flow and highlight where to apply it for maximum impact.

What is e-commerce order fulfillment?

E-commerce order fulfillment refers to the process that takes an online purchase from click to doorstep—covering every step in between. In simple terms, it’s everything that happens after your customer clicks “Buy” and before their order gets delivered.

Key stages of the fulfillment flow:

- Order receipt and processing: The order enters your system, is verified, inventory availability is checked, and is routed for picking.

- Picking and packing: Staff or automation conditions pull the correct item(s), pack them securely, add labels, and prepare for shipping.

- Shipping and delivery: Packages are handed off to carriers, transit begins, and the delivery is completed.

- Returns: If and when products are returned, they’re handled separately. Returned items are inspected, restocked, or processed for refund.

Managing all these moves manually—especially across spreadsheets and siloed systems—is where friction builds fastest, order accuracy drops, and visibility vanishes. Unless automated, these steps can quickly become hurdles.

A survey found that 85% of shoppers will not return after a poor delivery experience, underscoring how vital each fulfillment step is.

Why manual fulfillment creates bottlenecks

Manual fulfillment can introduce various operational bottlenecks, such as delays, errors, poor visibility, and seasonal staffing headaches. Here’s how these bottlenecks interrupt your operations:

- Copy/paste errors

- Data entry mistakes are surprisingly common.

- Manual data entry has an error rate of up to 4%, meaning that for every 100 orders, four contain mistakes, such as wrong SKUs or quantities.

- Inventory overselling

- About 43% of U.S. small businesses either don’t track inventory or rely on outdated manual systems, which can result in stockouts and lost sales.

- Shipment delays from miscommunication

- Communication gaps across disconnected platforms or email cause wrong shipments, delays, duplication, and frustrated customers.

- Limited scalability during peak season

- Manual workflows can’t scale with demand.

- Order volumes can spike between 200% and 400%, leading to up to a 30% productivity drop when operations rely on spreadsheets and manual processes.

- Without automation, even modest demand surges cripple fulfillment.

How automation solves fulfillment challenges

Automation doesn’t just speed things up; it removes friction points across your entire fulfillment operation. Here’s how:

- Faster order processing and validation

- The automated system instantly verifies orders, checks availability, and reduces delays, cutting processing times by up to 70% while dropping error rates from 5% to below 1%.

- Real-time inventory syncing

- Automation keeps stock levels updated across channels instantly.

- Retailers using optimized inventory systems see a 30% improvement in fulfillment rates, which reduces delivery delays and boosts customer trust.

- Smart picking and packing workflows

- Automated job assignment—including smart, algorithm-driven picks and batch packing—streamlines operations, reduces mistakes, and keeps throughput consistent, even in peak periods.

- Dynamic order routing

- Automation evaluates real-time variables—inventory levels, proximity, margins—to route each order to the ideal fulfillment source, enhancing speed and profitability.

- Carrier selection and label printing

- Built-in logic automatically selects the most cost-effective shipping carrier, prints accurate labels, and speeds handoff—eliminating manual carrier decisions and label misprints.

Automation speeds things up and helps remove friction:

- Consistent accuracy ensures few errors, returns, and customer complaints.

- Better visibility helps operations stay in sync across teams and channels.

- Scalability allows fulfillment to flex with demand—no extra staffing scramble needed during holidays or flash sales.

Where to start automating the fulfillment process

Automation can feel daunting; however, your team doesn’t need to overhaul everything overnight. Here’s how you can start smart:

- Implementing an OMS

- An agentic commerce platform like fabric centralizes orders from every channel, streamlining processing and reducing errors.

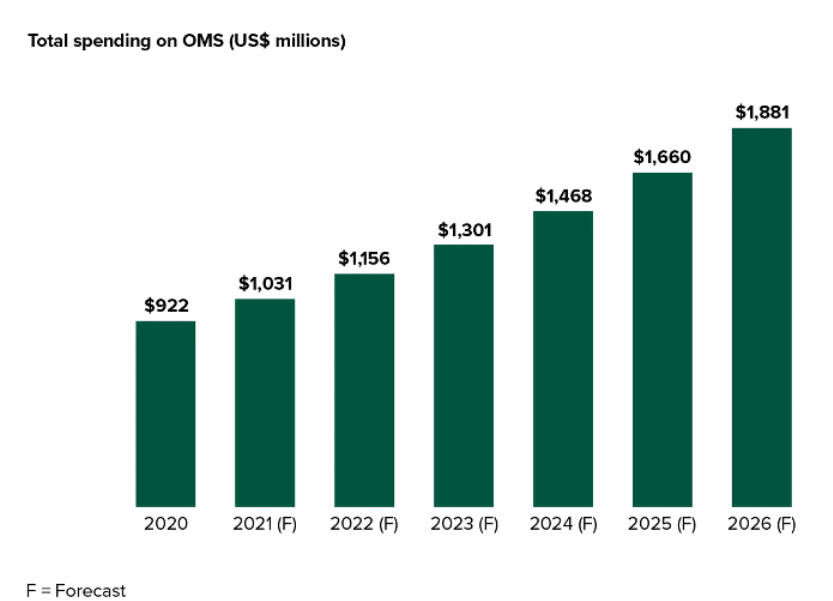

- The global OMS software market is projected to nearly double, from over $1 billion in 2021 to almost $1.9 billion in 2026, reflecting a CAGR of 12.3%.

- This surge underscores why OMS adoption is one of the smartest steps in automation.

Source: Forrester

- Automating order routing rules

- Set logical rules to route each order based on real-time factors like inventory, cost, and proximity.

- Our platform’s smart order routing capabilities let you automate this intelligently and at scale.

- Connecting WMS or 3PL systems

- Integrating warehouse management systems (WMS) or third-party logistics (3PL) platforms ensures seamless inventory and order flow, with no manual syncs and fewer inventory gaps.

- Using predictive inventory tools

- Predict demand to keep stock levels optimal, reduce overstocks or stockouts, and better manage replenishment cycles ahead of peak periods.

What to look for in an automated order fulfillment solution

Use this checklist to evaluate automation tools that move beyond basic mechanics to strategic order orchestration:

- Real-time inventory tracking

- Look for systems that unify inventory across warehouses, stores, and third-party sellers.

- fabric’s unified inventory management ensures you know exactly what’s available, wherever it is.

- Smart order routing

- Automation should route orders based on real-time data, like inventory location, fulfillment cost, and delivery proximity.

- fabric’s smart order routing makes this both configurable and agile.

- AI-driven demand forecasting

- AI-powered forecasting can improve accuracy and cut supply chain errors by 20% to 50%, along with benefits such as reduced lost sales and improved operational efficiency.

- Multi-channel integration

- Your OMS should manage orders from web stores, marketplaces, social platforms, and physical outlets in one unified workflow—no manual re-entry required.

- Returns processing

- Returns aren’t just about reverse logistics; they’re a source of customer loyalty.

- Automation should handle returns transparently, logging items, restocking, refunding, and syncing inventory in real time.

How automation leads to happier customers

Automation doesn’t just optimize your operations; it also elevates the customer experience.

- Fewer order issues: Automated systems reduce order inaccuracy and miscommunication, reducing complaints and exceptions across the fulfillment flow.

- More accurate deliveries: With real-time tracking and smarter routing, orders arrive correctly on time—making your brand reliable in the eyes of your customers.

- Faster turnaround times: Instant order validation, dynamic routing, and seamless carrier handoffs mean products get into customers’ hands quicker—without additional manual effort.

- Better post-purchase experience: Automation streamlines return handling, visibility, and communication—turning a potential pain point into a trust-building moment.

A study shows that 84% of consumers will not return to shop with a retailer after just one poor delivery experience—making fulfillment quality a critical loyalty driver.

Fulfillment can be your growth engine

Fulfillment is no longer just an operational necessity; it’s a growth engine. Adopting automation can help you shift from a cost center to a strategic advantage.

Embracing automation helps your brands grow and move faster, eliminates costly human errors, delivers more consistent customer experiences, and creates a foundation for scalable growth.

Want to future-proof your fulfillment? Request a demo and explore how intelligent order management can help you confidently automate.

Digital content editorial team @ fabric