A Guide to Backorders. Pros and Cons for Retailers.

A backorder is an order for a product that’s temporarily out-of-stock, which is expected to be fulfilled and delivered to the customer when replenished to the retailer’s on-hand inventory.

Offering backorders has pros like increased sales opportunities and customer loyalty, but cons like replenishment risks and potential delays causing customer dissatisfaction.

An order management system (OMS) is essential for optimizing backorder inventory accuracy and keeping customers notified and in consent of their expected delivery date.

fabric OMS empowers businesses with advanced backorder capabilities, allowing them to seamlessly manage inventory and fulfill customer orders with efficiency and control.

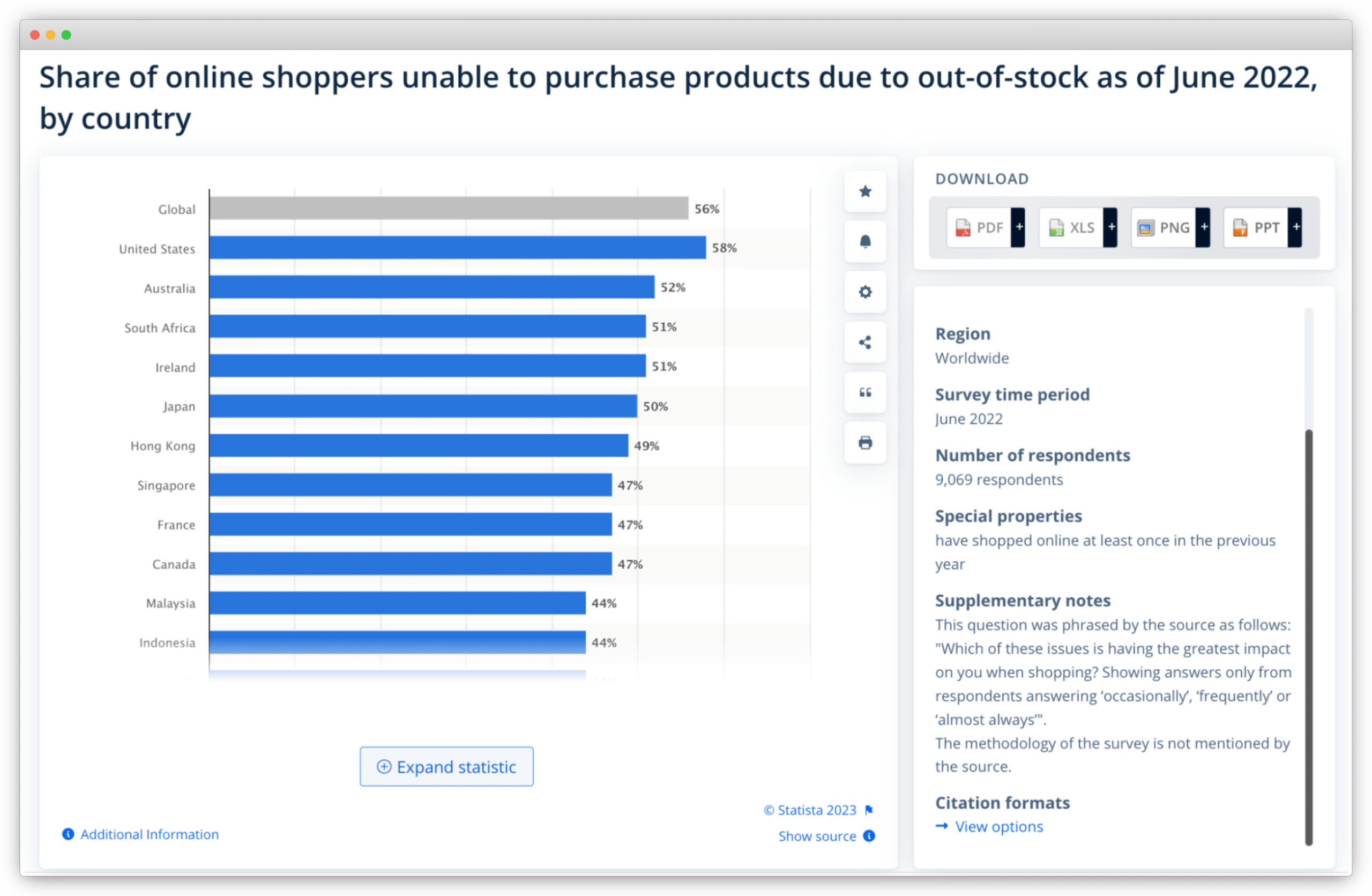

When asking shoppers about their experiences with online shopping, it is common to hear about frequent encounters with “out of stock” situations. In 2022, over half of global online shoppers reported being unable to purchase the products they wanted, and almost 60% felt that unavailability issues impacted their shopping behavior.

Efficient backorder management with a modern OMS

Offering backorders can provide several advantages for online businesses. Making inbound inventory available through backorders and automating inventory availability rules is a critical opportunity to improve customer experience and business performance.

Backorder inventory can be made available for every inventory replenishment. Order management platforms make it easy to automate backorder rules, like limiting orders for items on backorder and handling delays. With the right software, e-commerce brands can effectively manage backorders and decide whether to offer them to customers for various SKUs across different channels.

In this guide, we’ll cover:

- What backorders are

- The pros and cons of offering backorders

- How they work and when to offer them

- How to stay compliant with the FTC’s Prompt Delivery Rules

- Additional terms you should know include stockouts, preorders, depleted stock, and more

- What merchants can do to get the most out of offering backorders to customers

- Backorders FAQ

Let’s begin!

[toc-embed headline=”What is a Backorder?”]

What is a Backorder?

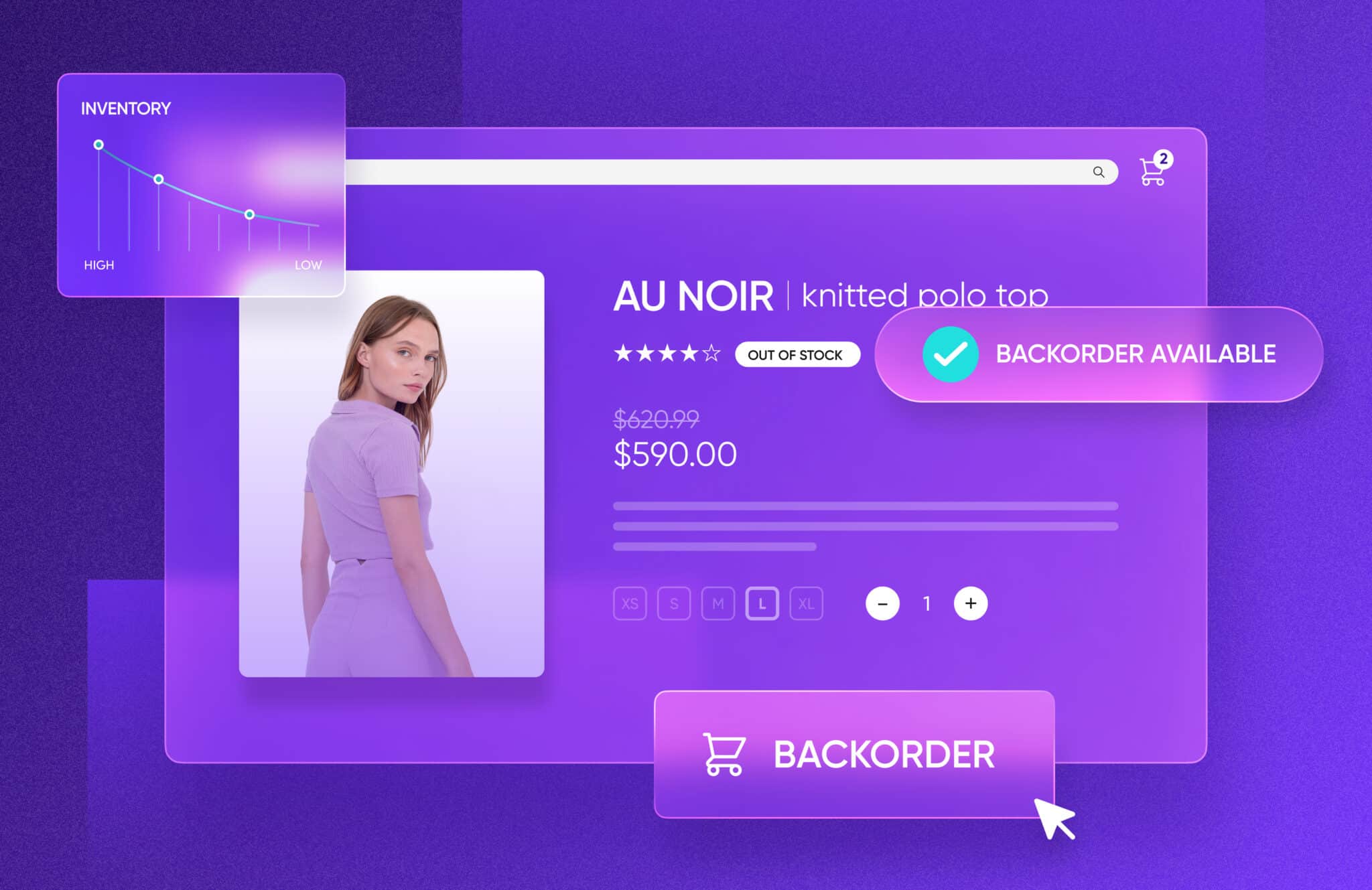

A backorder is an order for an out-of-stock product that will be fulfilled and delivered to the customer when the product is replenished. If customers place an order for a product that is currently unavailable for immediate shipment, typically due to it not being on hand and in the retailer’s fulfillment centers, then these orders are classified and called out as “backorder” during the purchase. The retailer notifies the customer the item is on backorder on the product page or in the order confirmation email, along with a date on which they estimate the item will be shipped.

Backorders indicate high demand for a product and allow retailers to capture sales even when inventory has temporarily run out. Offering backorders is inherently complex and requires a consistent and reliable customer experience.

For example, estimating demand for thousands of products is challenging, and coordinating with suppliers to replenish stock can be equally complicated. Furthermore, operational mishaps or miscommunications can lead to longer backorder times. They can cause retailers to misinform customers about when they can anticipate a delivery, negatively impacting customer satisfaction and loyalty.

Optimizing the backorder process using a robust inventory and order management system and forming solid relationships with suppliers can bolster a retailer’s ability to meet—even exceed—customer expectations.

Google Merchant Center

Google Merchant Center allows a company’s products to appear across Google websites and apps when customers search for product offerings or directly for a business. However, to use Google Merchant Center, businesses need to follow the formatting guidelines to ensure Google understands the data they submit.

[availability] attribute tells users and Google whether a business has a product in stock. The classifier [backorder] is typically applied for SKUs previously on hand but now out of stock. This is similar to the [preorder] classifier, which applies to SKUs that were not previously on hand and will be offered for the first time on a future date.

[toc-embed headline=”Benefits and Drawbacks of Accepting Backorders”]

Benefits and Drawbacks of Accepting Backorders

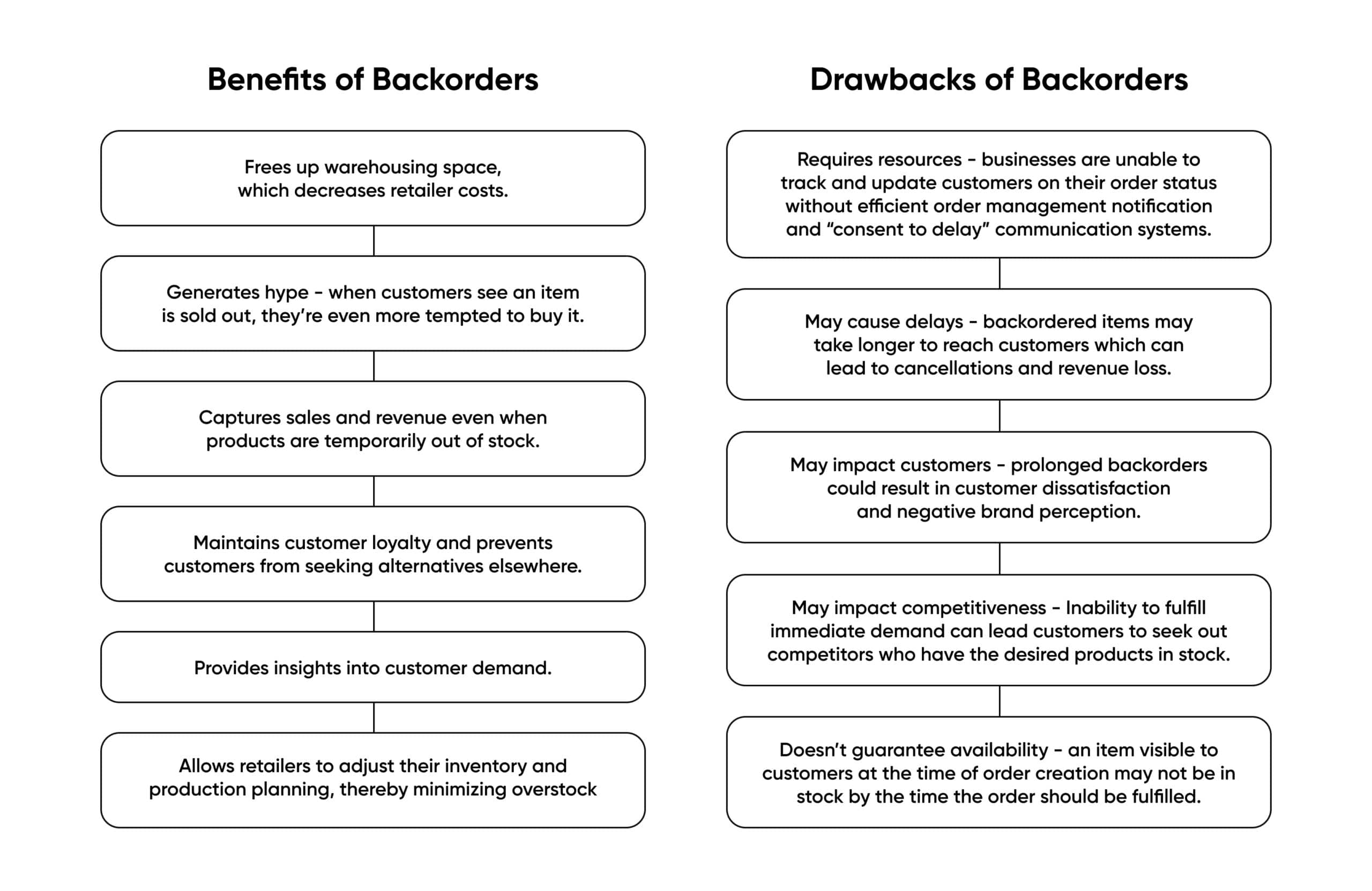

Backorders can benefit enterprise retailers and customers in myriad ways when handled appropriately. Below are some benefits and drawbacks of accepting backorders in e-commerce:

Pros and cons of backorders.

[toc-embed headline=”How do Backorders Work?”]

How do Backorders Work?

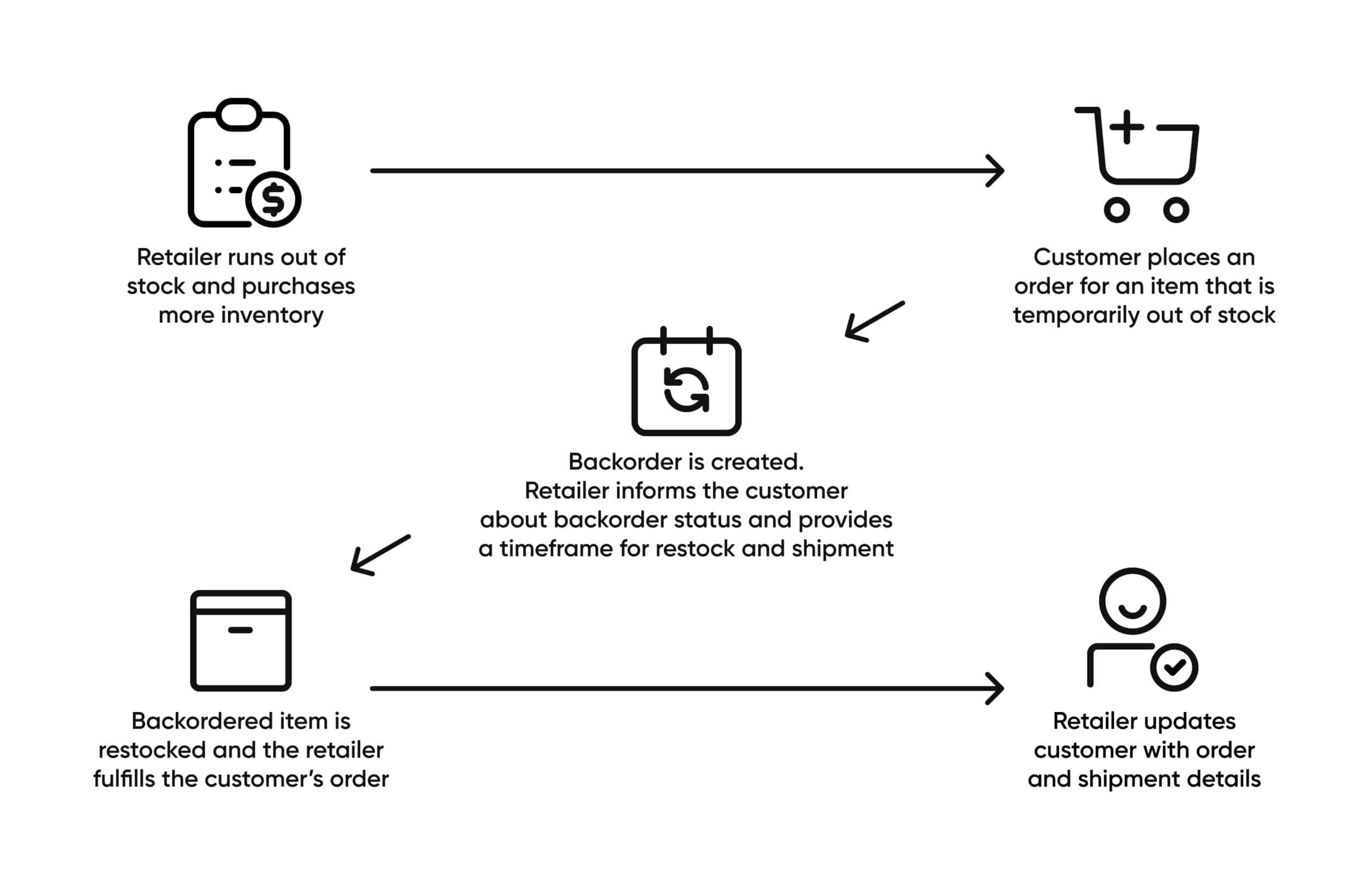

A backorder is created when a merchant runs out of stock and a customer places an order for an item that is temporarily out of stock.

Generally, large retailers monitor and control inventory availability either in the OMS or their e-commerce platform, in combination with data feeds from their enterprise resource planning (ERP) system, point-of-sale (POS) system, and warehouse management system (WMS). But how exactly do backorders work, and how do they impact the overall order fulfillment process? Let’s dive into the general process and mechanics of backorders:

1. Retailer runs out of stock and purchases more inventory

When an item runs out of stock across the fulfillment network of inventory locations, it will typically be flagged on sales channels to shoppers as “out of stock.” The retailer then purchases more inventory and receives the supplier’s estimated inventory receiving date. Retailers can also set their system up to automatically order more inventory from the item’s supplier when stock is running low. This process applies only to retailers operating as the merchant of record and housing first-party inventory.

2. Customer places an order for an item that is temporarily out of stock

Retailers may offer backorder inventory as part of the product lifecycle and replenishment management process. With backorder inventory, a shopper may select a product currently out of stock or unavailable for immediate fulfillment. Ideally, this information will be posted on the item’s product detail page with an estimated date for the item’s return in stock.

3. Backorder is created. The retailer informs the customer about the backorder status and provides a timeframe for restocking and shipment

The seller can create a backorder for the out-of-stock item, indicating that the customer’s order will be fulfilled once the item becomes available again. The retailer will generally provide an estimated timeframe for when the item will be back in stock and shipped.

4. Backordered item is restocked, and the retailer fulfills the customer’s order

Once the retailer receives additional inventory from the supplier, the order is allocated through the Fulfillment Automation process, which selects the best fulfillment center(s) for the order based on geography and other business parameters for fulfillment rules. Once the order is allocated for fulfillment to a warehouse or store, the picking and packaging process is conducted by fulfillment specialists to make the item ready for shipment or pickup.

5. Retailer updates customer with order and shipment details

With transactional emails and notifications, the retailer keeps in touch with the end customer throughout this process. Customers are notified when new inventory comes in and when their package is shipped and expected to be delivered.

[toc-embed headline=”Backorder Compliance With the FTC’s Prompt Delivery Rules”]

Backorder Compliance With the FTC’s Prompt Delivery Rules

Merchants must follow the Mail, Internet, or Telephone Order Merchandise Rule outlined by the FTC.

By law, online merchants must follow the Mail, Internet, or Telephone Order Merchandise Rule, which spells out the ground rules for making promises about shipments, notifying consumers about unexpected delays, and refunding consumers’ money. According to the FTC:

“You must have a reasonable basis for stating that a product can be shipped within a certain time. If your advertising doesn’t clearly and prominently state the shipment period, you must have a reasonable basis for believing that you can ship within 30 days.

If you can’t ship within the promised time (or within 30 days if you made no promise), you must notify the customer of the delay, provide a revised shipment date and explain his right to cancel and get a full and prompt refund.

For definite delays of up to 30 days, you may treat the customer’s silence as agreeing to the delay. But for longer or indefinite delays – and second and subsequent delays – you must get the customer’s written, electronic or verbal consent to the delay. If the customer doesn’t give you his okay, you must promptly refund all the money the customer paid you without being asked by the customer.

Finally, you have the right to cancel orders that you can’t fill in a timely manner, but you must promptly notify the customer of your decision and make a prompt refund.”

Because obtaining a customer’s “consent to delay” for backorders is legally required, large retailers with complex operations need to be aware of their legal exposures. Instead of manual processes, a market-leading order management system like fabric OMS can dramatically simplify the backorder “consent to delay” workflow by enabling customers to continually consent and receive notifications if the estimated delivery date changes. This self-service “no-code” feature eliminates the need for developer resources, allowing business users to maintain compliance and configure:

- When the consent to delay window starts.

- The consent to delay notification window and reminder notification window.

- The respective auto-cancellation windows for backorders that have and don’t have consent.

Check out fabric’s API reference docs for more.

[toc-embed headline=”Backorder vs. Out of Stock (Stockout)”]

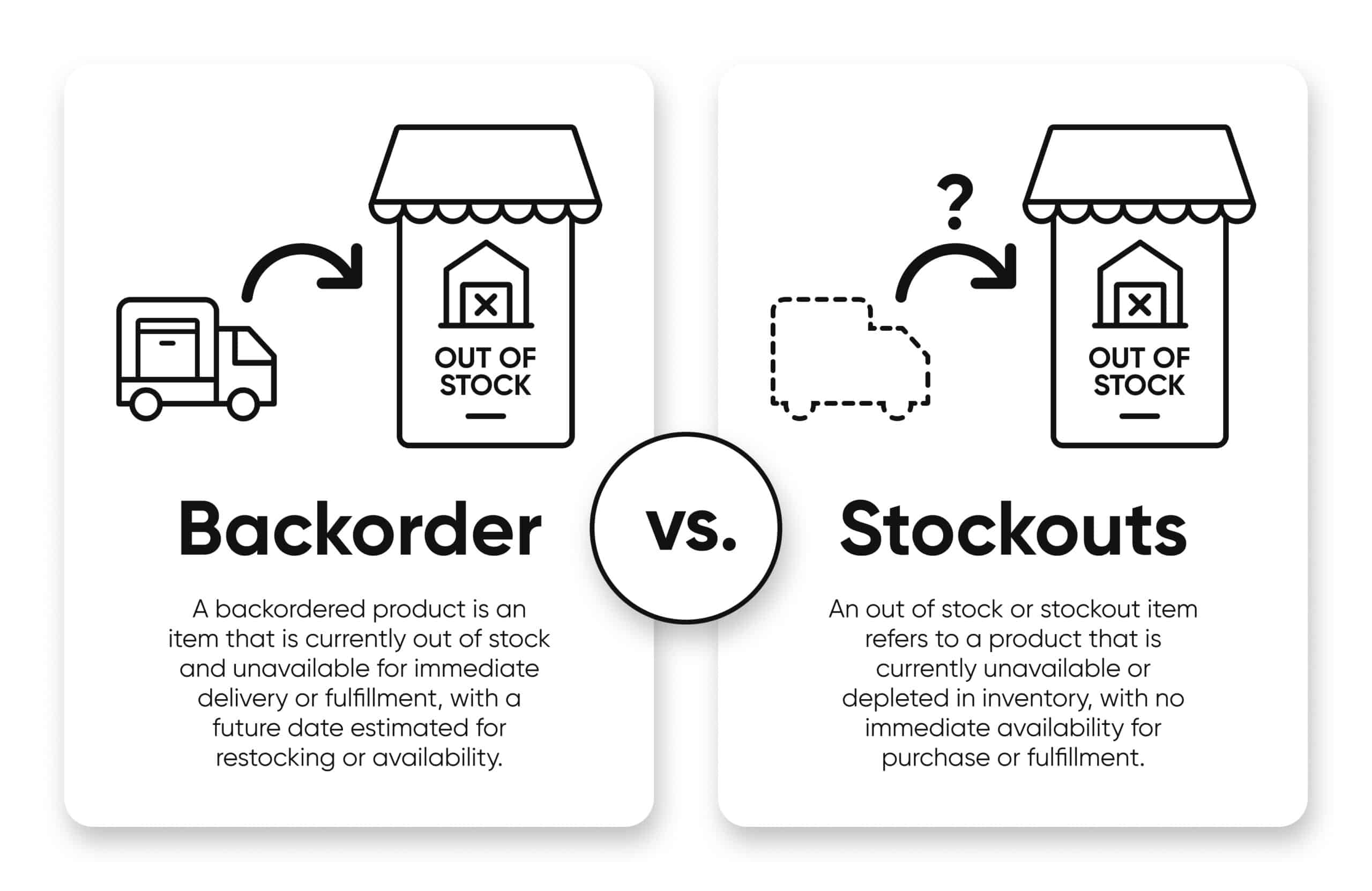

Backorder vs. Out of Stock (Stockout)

Out of stock (or stockout) items are simply products that are not available and can’t be purchased by customers. For example, an out of stock message might say, “This product is unavailable,” conveying to the consumer that the item may be unavailable permanently.

There are a few other terms retailers use to keep track of and replenish their inventory:

- Preorders, or orders for products that are not yet available but will be for sale soon. Customers can preorder items, and they will ship when they are available for sale.

- Depleted stock, which means that the quantity of an item is critically low, or has reached zero, or has fallen below a predefined threshold.

- Non-stocked, which means that a retailer does not hold an item in physical inventory. Retailers can use alternative methods like dropshipping or third-party suppliers.

- Awaiting shipment/pickup, which indicates that an item has been picked, packed, and is pending pickup or delivery by the shipping carrier.

- Back stock or safety stock, which refers to inventory that is not immediately needed and is kept in reserve to ensure continuous availability.

- Dead stock, which refers to inventory that has remained unsold and unused for a long period of time. Unsellable stock can arise after a company orders or manufactures too many items.

[toc-embed headline=”What Causes Backorders?”]

What Causes Backorders?

Many things can influence whether an item is backordered, ranging from surges in demand to supplier problems to operational issues. Below, we describe some issues that retailers may experience.

Unpredictable demand

Demand for a certain product can surge when launching a new sales channel or region or after a viral event, such as a TV appearance or celebrity mention. As a result, the available inventory quickly sells out, and fulfilling all the backorders can take an extended period of time due to the high demand and limited supply.

Inventory mismanagement

Various issues can arise with inventory management. Products can go missing, be misplaced, or become damaged during transportation within a facility. Additionally, inefficient order management systems and faulty connections to supplier portals can contribute to inventory problems downstream. When available stock doesn’t match the projected demand, it can lead to overselling and ultimately result in backorders.

Seasonal fluctuations

With retail seasonality, consumer-facing companies earn 50% or more of their annual revenue in Q4. Peak shopping periods place stress on suppliers that may not be working at full capacity or may run out of items themselves. Retailers may also fail to accurately forecast demand and prepare for fluctuations by adjusting their inventory levels and supply chain processes, leaving customers in the lurch.

Order processing or manual processing issues

Order processing issues that can cause backorders include manual errors in order entry, inaccuracies in inventory management or stock counts, and delays in processing and fulfilling orders due to inefficient workflows or lack of automation. These issues can lead to discrepancies between available stock and customer demand.

Supplier delays

Some suppliers contract with other third-party companies that make parts of the products they sell to retailers. Suppliers can’t hit your service-level agreements (SLAs) when third-party companies don’t hit production deadlines, meaning you may burn through your safety stock and have to put items on backorder.

Manufacturing or supply chain issues

Even if you order your inventory on time, things can go wrong in the production process. Specific materials needed to create products may be inaccessible or no longer available. Tariffs and labor shortages can disrupt the supply chain. And if suppliers can’t ship inventory as promised, your inventory will run out faster than expected, warranting a backorder.

[toc-embed headline=”5 Tips for Getting The Most out of Backorders”]

5 Tips for Getting The Most out of Backorders

There are a few things enterprise retailers can do to maximize the benefits of accepting backorders without exposing the company to too much risk.

1. Implement advanced inventory controls for better accuracy

A modern OMS gives retailers the ability to manage orders, inventory, and fulfillment with a single system, which can allow businesses to enjoy the benefits of offering backorders, without the drawbacks. By maintaining accurate and up-to-date inventory visibility through real-time monitoring and tracking systems, a business can proactively identify potential stock shortages, replenish inventory in a timely manner, and provide customers with accurate information about product availability.

2. Create safety stock

Safety stock, or back stock, acts as “insurance” inventory for high-demand products. The extra inventory gives companies a buffer during supply chain delays, unexpected sales spikes, or longer-than-expected lead times for restocking. Enterprise e-commerce companies often pre-order additional inventory ahead of highly-anticipated product releases and the holiday season to reduce the need for backorders.

3. Work with reliable suppliers

Suppliers are a key piece of the order management puzzle—enterprise retailers need them to deliver products on time and in excellent condition. Building relationships with those suppliers upfront, integrating your inventory management system with their portals, and optimizing standard operating procedures over time can dramatically decrease the risk of late or missed deliveries that force backorders.

4. Use an order management system

OMS systems are key for managing and displaying available inventory. A fully-featured OMS should give retailers insight into on-shelf, in-transit, and on-order inventory in real time and across warehouses, stores, suppliers, and distribution centers.

A distributed order management (DOM) system takes a traditional OMS system to the next level, using automation to determine optimal fulfillment locations based on logic-based rules. With order fulfillment logic in place, your OMS can show inventory by store, network, and geography, thereby enabling your team to deliver customer orders through virtually any sales channel.

Another plus is that admins can set specific inventory controls based on the level of safety stock to reduce the chances of running out. And they can also use a modern OMS to configure inventory position tags and custom attributes that keep their warehouses operating efficiently.

5. Use demand forecasting

Analyzing customer, order, and supplier data gives retailers an idea of which items are most popular and how long it takes to restock them, on average. With this information in mind, they can better predict how much inventory and safety stock they need to avoid stockouts. And if backorders can’t be avoided, demand forecasting helps retailers give customers more accurate delivery dates.

[toc-embed headline=”Backorder Inventory Management With fabric OMS”]

Backorder Inventory Management With fabric OMS

To strike a balance and reap the benefits of backorders without the drawbacks of revenue loss and customer dissatisfaction, enterprise retailers must focus on implementing the right tools and processes, starting with effective inventory and order management strategies. fabric OMS is a distributed order management (DOM) system built specifically to address the challenges enterprise retail brands face.

In addition to accepting backorders, businesses can designate eligible inventory that is permitted to be sold when the products are not on hand. fabric OMS will automatically convert orders to backorders and then release them from the backorder designation as soon as inventory becomes available. Retailers can exercise further control by setting limits on the number of backorders allowed per item.

fabric OMS empowers businesses with advanced backorder capabilities, allowing them to seamlessly manage inventory and fulfill customer orders with efficiency and control. Learn more about all that fabric OMS has to offer by setting up a demo with our team today.

[toc-embed headline=”Backorder FAQs”]

Backorder FAQs

What is a backordered item?

A backordered item indicates that the product is currently unavailable for immediate shipment. Retailers notify customers that the item is on backorder on its product page or in an order confirmation email, along with a date they estimate the item will be shipped.

Are backorders bad for your business?

Backorders have pros and cons.

Customers may decide that backorder times are too long and research other retailers who can deliver the product they want sooner. Failing to manage customer expectations can lead to churn as well. Moreover, backorders can increase the load on customer service, as customers may contact them frequently for order updates.

At the same time, backorders can allow businesses to capture sales and revenue even when products are temporarily out of stock. They also free up space in a retailer’s inventory, give retailers insight into customer trends and behavior, and generate hype about certain products. The key to realizing these benefits is to leverage a modern order management system that can simplify and automate parts of the backorder process.

What is the difference between backorder and out of stock?

People confuse backorder and out of stock because they both mean that inventory is unavailable. The difference is that backorders have a definitive date of resupply, while out of stock items do not.

What does partial backorder mean?

A partial backorder refers to a situation where a customer’s order contains multiple items, but only some of them are available to ship. To keep the customer happy, the retailer ships the items that are in stock and places the rest on backorder to be delivered at a later date.

How long do backorders take?

The length of time an item is on backorder depends on how fast suppliers can get retailers new inventory. One way to shorten backorder times is to source dropshippers who will send replenished items directly to the consumer instead of shipping the inventory to the retailer first.

Digital content editorial team @ fabric