How AI-Driven Order Management Transforms Business Operations

Traditional, non-AI-driven order management systems struggle with the complexities of modern omnichannel retail, leading to operational bottlenecks like inaccurate inventory, slow processing, and poor customer experience across multiple channels.

An AI-powered order management system (OMS) offers a solution by providing intelligent automation, real-time data analysis for dynamic routing and exception handling, and data-driven insights to streamline workflows, reduce costs, and enhance the customer journey.

Imagine this: you’re a national-level retailer running a holiday promotion across multiple channels—your website, mobile app, and in-store locations. Orders are flooding in. But the order management system (OMS) that you’re relying on? It’s outdated, clunky, and stitched together with manual workarounds. Stock levels are off, order processing is lagging, and no one seems to know which distribution centers can actually fulfill the demands. Sounds familiar?

This is the daily life for businesses still relying on traditional, non-AI-driven systems. As customer expectations and shopping habits evolve, so does the complexity behind the scenes. Consumers today move seamlessly across platforms, digital channels, in-store, and third-party marketplaces, and they expect a unified platform to meet them where they are. Yet many retailers are still relying on tools that aren’t built for this level of scale or agility.

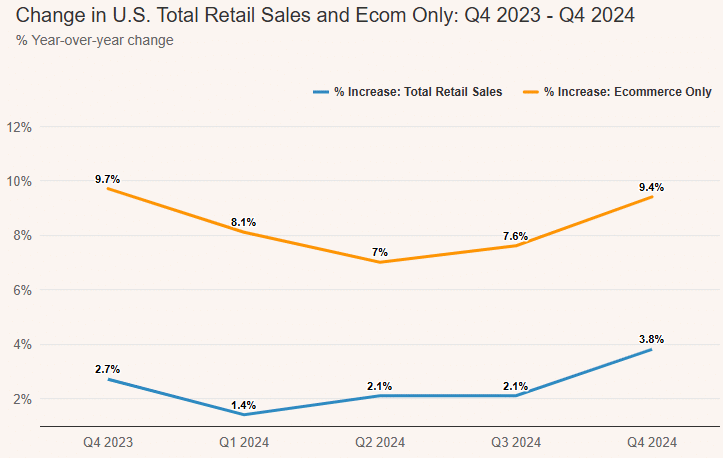

With time, the stakes are only rising. In Q4 2024, online purchases made up 16.4% of all U.S. retail sales, totaling $308.9 billion, a 9.4% increase from the previous year, according to the U.S. Census Bureau. As order volume grows, so does the pressure to deliver fast, accurately, and cost-effectively.

Source: PracticalEcommerce

This is where AI comes in. An AI-powered order management system (OMS) connects the dots across the entire supply chain, from order capture and inventory availability to intelligent order routing, automated returns management, and proactive exception handling. It uses real-time data to streamline operations, reduce fulfilment costs, and improve the customer experience at every touchpoint.

In this article, we’ll review how AI is redefining the order management process, not just by making it faster, but by making it smarter. We’ll explore key capabilities to look for in a next-gen system and how it supports business growth through operational efficiency, scalability, and seamless integration.

Pinpointing operational bottlenecks in traditional OMS

Before we explore how AI can enhance your operations, it’s essential to understand the core challenges you face with traditional systems. These challenges are more than just minor inefficiencies—they’re structural barriers that hinder growth and erode customer satisfaction.

Many retailers are still relying on outdated computer software systems that weren’t designed for the demands of digital channels, multiple partners, or modern distribution channels. These systems often operate in silos, requiring your teams to reconcile inventory levels manually, update shipping details, and manage order entry across various platforms.

The lack of real-time visibility and data synchronization leads to mismatches in inventory availability, delays in processing orders, and errors in order fulfillment.

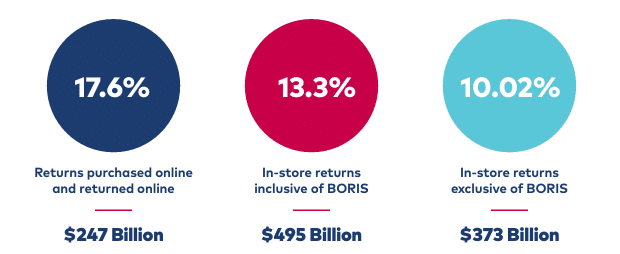

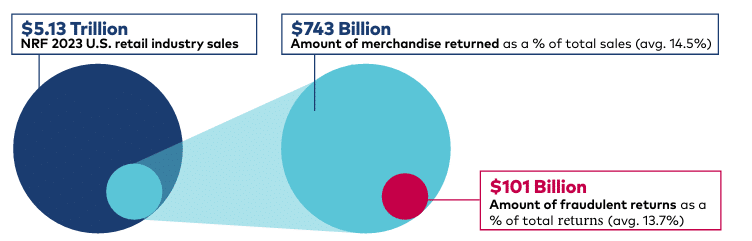

The financial impact of these inefficiencies is massive. According to the National Retail Federation’s 2023 Consumer Returns in the Retail Industry report, U.S. retailers saw $743.85 billion in merchandise returned, representing 14.5% of total retail sales. Online orders were hit hardest, with a 17.6% return rate, while in-store purchases saw a 13.3% return rate.

Source: National Retail Federation

Perhaps more concerning, over $101.9 billion of those returns were flagged as fraudulent or abusive, revealing a deeper issue with poor inventory control, an inadequate validation system, and gaps in the entire process.

Source: National Retail Federation

For teams managing large volumes of customer orders, the cracks in the system show quickly. Without a centralized, integrated order management system, it’s harder to track orders, fulfill them promptly, or provide proactive customer service when issues arise. Combined together, it results in lost sales, frustrated customers, and missed opportunities to scale.

And this is why a shift to an intelligent, adaptive approach is not just necessary, but critical. AI enables you to overcome these bottlenecks by replacing fragmented workflows with a single system that automates decision-making, connects data across the supply chain, and improves accuracy at every stage of the order management process.

AI-powered order management: Driving operational excellence

Transitioning from outdated systems to AI-powered platforms isn’t just a tech upgrade—it’s a shift in operational strategy. The best order management systems (OMS) are built to do more than just process transactions. They’re designed to think, adapt, and scale.

Here’s how AI can drive efficiency, precision, and resilience across the entire supply chain.

Intelligent automation for streamlined workflows

AI-driven automation is transforming how you can manage the order management process. By taking over repetitive and time-consuming tasks, such as order entry, inputting shipping details, and syncing inventory, AI frees up your team to focus on high-value work, like improving the customer experience and resolving exceptions.

This automation speeds up order processing, reduces errors, and improves accuracy across multiple channels. Instead of relying on reactive corrections, AI ensures that every step from order capture to returns management follows a predictable and optimized flow.

The global appetite for automation is growing rapidly. In fact, the industrial automation and control systems market is projected to more than double in value, from $379.47 billion in 2023 to over $864.94 billion by 2031, with an expected CAGR of 10.8% between 2024 and 2031. This upward trend signals that companies are doubling down on automation to reduce costs, improve accuracy, and scale their operations.

Dynamic routing and real-time optimization

Traditional order fulfilment often follows static rules that don’t adjust for real-world variables. AI changes that by using real-time data, from weather, traffic, and inventory conditions, to determine the most efficient ways to route orders from the warehouse to the doorstep of your customer.

Whether you’re shipping from distribution centers, enabling in-store pickup, or fulfilling through multiple partners, AI identifies the best path in real time, resulting in faster deliveries, lower shipping costs, and fewer fulfillment bottlenecks.

And in case of unexpected events, such as a weather change, a sudden stockout, or a last-minute address change, AI adapts instantly. It reroutes, reallocates, and ensures that the customer receives their order on time.

This kind of agility is especially crucial as customers expect seamless service regardless of the complexity behind the scenes.

Proactive exception management and risk mitigation

In the business world, two things are inevitable: taxes and disruptions. While taxes are scheduled and predictable, operational hiccups such as shipping delays, inventory mismatches, or supplier issues often aren’t.

Instead of reacting to the issues after they occur, AI anticipates potential exceptions by analyzing real-time data from across the entire supply chain. It can flag risks before they escalate, such as a distribution center running low on stock or a spike in returns from a specific sales channel, and reroute orders or adjust fulfillment rules to keep things moving smoothly.

This approach can help your teams reduce errors, cut down on firefighting, and stay ahead of disruptions. It’s especially powerful in high-volume environments where customer orders are managed on a large scale.

AI also plays a critical role in reducing the financial and reputational cost of failure. When exceptions are caught early and handled intelligently, you can avoid costly missteps, protect margins, and most importantly, retain trust. After all, consistency is a key driver of customer satisfaction, and when a customer receives their order without a hitch, they’re far more likely to come back.

Data-driven insights for operational improvement

Modern commerce generates an enormous amount of data from every purchase order, sales order, and return point. AI leverages this data to identify patterns and bottlenecks that manual reviews often miss.

It delivers real-time insights that can help you fine-tune inventory management, optimize warehouse layouts, and refine your order orchestration strategy. These insights aren’t just for your present performance; they’re also critical for predicting demand spikes, setting accurate recorder points, and scaling into new markets with confidence.

Enhanced resource allocation and cost reduction

One of AI’s most powerful contributions lies in how it can help you allocate your resources. By analyzing historical performance and forecasting future demands, AI can recommend where to position inventory, how to schedule shifts, and when to ramp up logistics support.

This ensures your operations are lean, but never underpowered. Better inventory control, fewer overages, and reduced warehouse downtime directly impact your bottom-line savings.

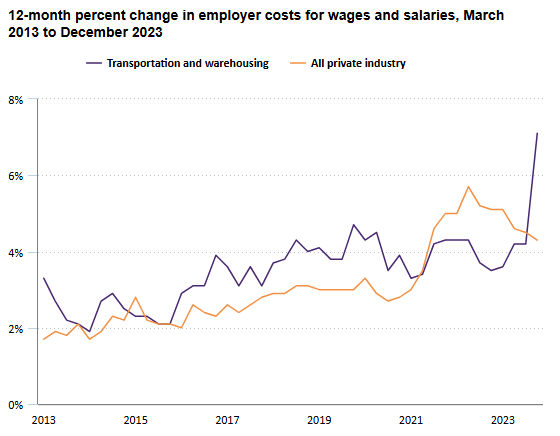

A report from the U.S. Bureau of Labor Statistics highlights that labor costs for transportation and warehouses, which include supply chain and warehouse operations, increased by 7.1% in 2023, marking the steepest 12-month rise since records began in 2001. That kind of inflation puts serious pressure on retailers managing high volumes of orders across multiple channels.

Source: U.S. Bureau of Labor Statistics (Slide 6)

Strategic implementation: Aligning OMS with operations

Adopting an AI-powered OMS isn’t just about upgrading your tech stack; it’s about reshaping how your business runs behind the scenes. For long-term impact, the system needs to be aligned with your operational goals, data architecture, and workforce readiness from the start.

A smart implementation begins with clarity. Whether your focus is on reducing shipping costs, improving inventory visibility, expanding into new markets, or simplifying return management, the system should align directly with those objectives.

However, that would be ineffective without proper data integration. AI-powered OMS platforms thrive on real-time data pulled from across the supply chain, including ERP systems, warehouse platforms, POS tools, and even call centers. When your inventory management and order capture systems are fully connected, you can unlock more accurate forecasting, better inventory control, and faster order fulfilment.

Equally important is preparing your team to operate this unified platform with confidence. AI may streamline workflows, but your team still plays a vital role. It’s crucial to invest in a clear onboarding process and role-specific training that focuses on how to manage customer orders, interpret real-time insights, and navigate the new order management software interface.

Ultimately, a successful implementation is about syncing your people, platforms, and processes around a single system that’s built for speed, scale, and adaptability.

Experience the strategic advantage of an AI-driven OMS

An AI-powered OMS does more than just modernize your operations; it gives you a strategic edge. By replacing outdated manual processes with intelligent automation, you can streamline the entire process from order capture to order fulfillment, improving inventory visibility and adapting to real-time shifts in demand, logistics, and customer behavior.

Whether you’re scaling across distribution centers, expanding into new markets, or trying to improve your returns management operations, the right AI-driven OMS can support growth without adding more complexity.

Moreover, it’s not just about technology; it’s about transformation. With a single system that can unify your workflows and surface actionable, real-time insights, you’re no longer dealing with issues; you’re proactively managing the future of your business.

Unlock new levels of performance by learning how fabric’s OMS can empower you to align your tech with your goals. Drive smarter decisions and deliver an exceptional customer experience with fabric’s centralized and comprehensive OMS.

Digital content editorial team @ fabric