From Woes to Wins: 4 Inventory Management Tips to Transform Your Supply Chain

Over recent years, delays and disruptions in the global supply chain have wreaked havoc on product lead times and threatened total paralysis for industries. Bottlenecks due to the pandemic, a shortage of shipping containers, never-before-seen port congestion, lack of infrastructure, and limited transport capacity and skilled labor are just a few examples of the chaotic economic environment that businesses have had to navigate—and continue to do so today.

And the change isn’t going to slow down. According to Supply Chain Management Review, upcoming trends in big data, advanced analytics, supply chain digitization, data management, and process standardization are all poised to make a major impact on supply chains this year—and beyond.

So what can your business do in response? The first is making an investment in technology that will make your operations more efficient. For example, by utilizing modern inventory management software, businesses can benefit immensely from simple improvements that can squeeze out efficiencies along the entire retail supply chain.

Here are a few tips that mid-market and enterprise brands can utilize to combat supply chain disruptions:

Tip #1: Improve visibility across the retail supply chain

One of the most critical improvements that businesses can make is optimizing inventory visibility. In a supply network where product fulfillment data can come from multiple channels, modern inventory management software can use aggregation to expose the full availability of inventory across the entire network.

This helps to minimize stock outs and order cancellations, satisfy service-level agreements (SLAs), and create a better fulfillment experience for the customer.

Perhaps the most important functionality that businesses lack is the syncing of inventory across sales channels and locations. Without a real-time, 360-degree view of inventory availability, it becomes increasingly difficult to track inventory across a vast network, let alone use OFL to route products to optimal locations for streamlined fulfillment.

The good news is that syncing inventory does more than just improve visibility. It also allows businesses to manage accurate buffer inventory levels (the excess inventory reserves to protect against unforeseen circumstances), optimize available-to-promise (ATP) inventory (the projected amount of inventory a business has in stock, ready to sell and not allocated for existing customer orders), view stock that is available in-transit, and view inventory positions by various channels or warehouses.

Precise, real-time data can help businesses increase inventory turns and reduce markdowns, and allow them to support multi/omnichannel models, including buy-online-pickup-in-store (BOPIS), ship-to-store, and store fulfillment (as mini distribution centers).

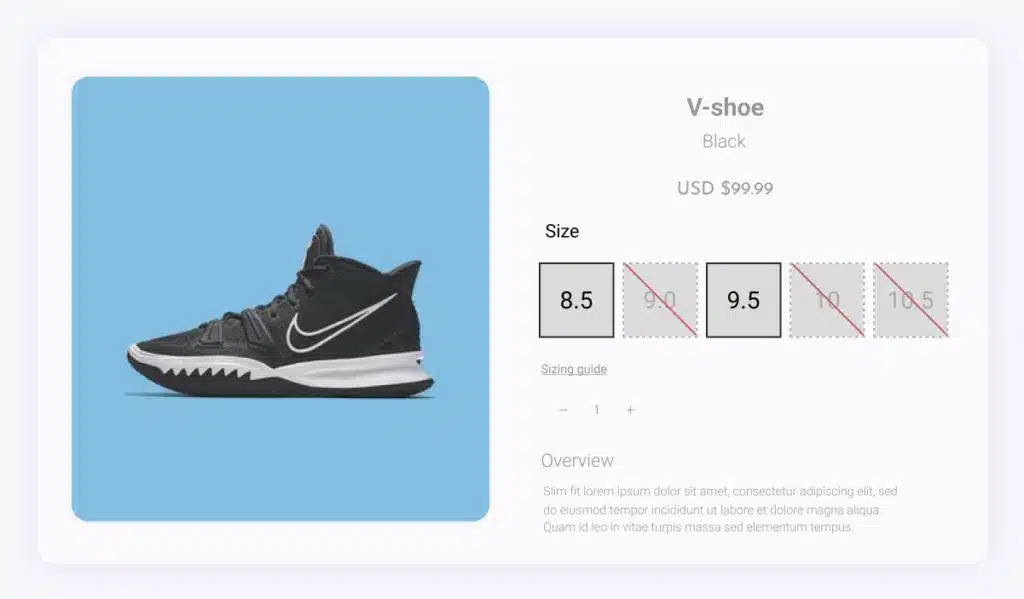

Syncing inventory to product detail pages (PDPs) on an e-commerce storefront can also inform customers about the exact amount of ATP stock they’re looking to purchase.

Tip #2: Forecast—and plan for—demand using pre-ordering and backordering mechanisms

Demand forecasting uses predictive analysis to understand and predict customer demand and future sales by using historical sales data, trends, and known upcoming events to make informed decisions.

Types of products, geography, seasonality, and competition can all influence consumer demand, which is why businesses often use agile demand forecasting models to plan inventory and warehousing needs and to respond quickly to unforeseen circumstances.

Demand forecasting generally happens with an enterprise resource planning (ERP) platform or with standalone demand planning software such as Netstock, SAP Business Planning, and IBM Planning Analytics.

But forecasting is only as good as the data that it’s given. This is why modern OMS applications offer pre-order and backorder mechanisms to get a better sense of the amount of inventory that’s required to meet customer expectations. Typically, a modern OMS application can aggregate the future demand of products with pre-order and backorder capabilities, and send that data to a demand planning system to forecast demand and plan future inventory requirements.

Take pre-orders: They are an excellent way for businesses to build hype, gauge demand, and adjust inventory levels in preparation for the launch of a new product or service. It can lower the financial risk of selling a new product and simultaneously build excitement and anticipation leading up to a product’s release. ATP inventory not only helps businesses keep enough inventory available to be sold, but it also anticipates future requirements using data-based forecasts.

With pre-order capabilities, companies can sell items before they are ATP and release them on the specified pre-order release date that they become ATP.

Meanwhile, backorders allow a business to still complete a sale and retain its customer, while also helping the company to assess its inventory requirements.

Tip #3: Lean on inventory control applications

A subset of inventory management is inventory control, or stock control. Inventory control ensures the optimal amount of supplies within a business. It also seeks to maximize profit while minimizing the total cost of inventory, while still providing customers with products in a timely and efficient way.

Modern inventory management software is often equipped with inventory control systems, making it easier for retailers to optimize stock levels and extend the data model to fit business needs.

A well-functioning inventory control system should allow companies to categorize inventory by attributes, locate items, pool inventory, and control the availability of stock to sell in each channel, market, or region.

It should also allow them to set accurate and specific reorder points to replenish stock when needed. Companies can use software to plan for sales and stock-outs and prevent the buildup of dead stock, also known as unsold inventory, that sits in storage and is not expected to be sold in the near future.

A few important software features include:

- Network aggregation of inventory

- Visibility into global, local, and available-to-promise (ATP) inventory

- Bulk actions to upload vendor inventory

- Product feed integration

- Automation of tedious and labor-intensive processes (eliminate manual spreadsheets)

- Low code/no code configuration of inventory management, multiple warehousing, and fulfillment rules

- Custom inventory attributes and positions to categorize and organize inventory

- Safety stock and low stock settings

- Enhanced pre-order and backorder capabilities with inbound inventory allocation

Tip #4: Invest in third-party inventory management software

Not all third-party inventory management software vendors are created equal.

Because every business has its own unique requirements, companies that want to eliminate manual spreadsheets or abandon legacy inventory management applications in favor of modern inventory management software should assess the market to see what offerings suit their individual needs.

Here are some important questions to ask when considering a modern inventory management system:

- Does the inventory management system easily connect with any enterprise resource planning (ERP) software, customer relationship management (CRM) software, or warehouse management system (WMS)?

- Does it work closely with order management processes?

- Does it easily integrate with your preferred applications using an open application programming interface (API) model?

- How long does it take to get the system up and running?

- Does it provide real-time updates on orders and inventory positions?

- Can the system add or remove warehouses quickly?

- Does it offer the latest features, like real-time inventory visibility, network aggregation, a pre-order/backorder engine, support for BOPIS, ship-to-store (for store pick up or replenishment), and store fulfillment (as mini distribution centers) models, bulk inventory import/export, and simple management of safety stock and low stock (to name a few)?

- How much does it cost? A complete TCO analysis of software is critical before any decision can be made.

fabric OMS: Modern inventory management software purpose-built for ecommerce

fabric’s order management system (OMS) is an API-first, cloud-native, and modular application that seamlessly combines inventory availability with order management and multi-channel fulfillment capabilities.

It provides a single tool with a 360-degree view of inventory across an entire network, and it gives retailers the power to manage and distribute inventory to enable fully optimized omnichannel order fulfillment journeys and connected operations.

fabric’s application is not only packed with all the latest features but it’s also built for performance and scale. Its serverless and API-first architecture supports business growth without additional technology costs and easily connects to any ERP, CRM or WMS system.

Plus, businesses can easily set inventory and fulfillment rules with configuration rather than code, and it’s powerful enough to be used as a standalone solution or as part of fabric’s comprehensive ecommerce platform.

If your business is looking to move away from a legacy inventory management system and wants to lower costs, boost margins, strengthen efficiency, and improve customer satisfaction, fabric’s market-leading OMS application may be just the ticket.

Product engineering @ fabric. Previously merchandising and application development @ Staples.