Master Your Stock: A retailer’s blueprint for improving inventory health

Inventory health is about maintaining the right balance between stock levels, customer demand, and operational costs.

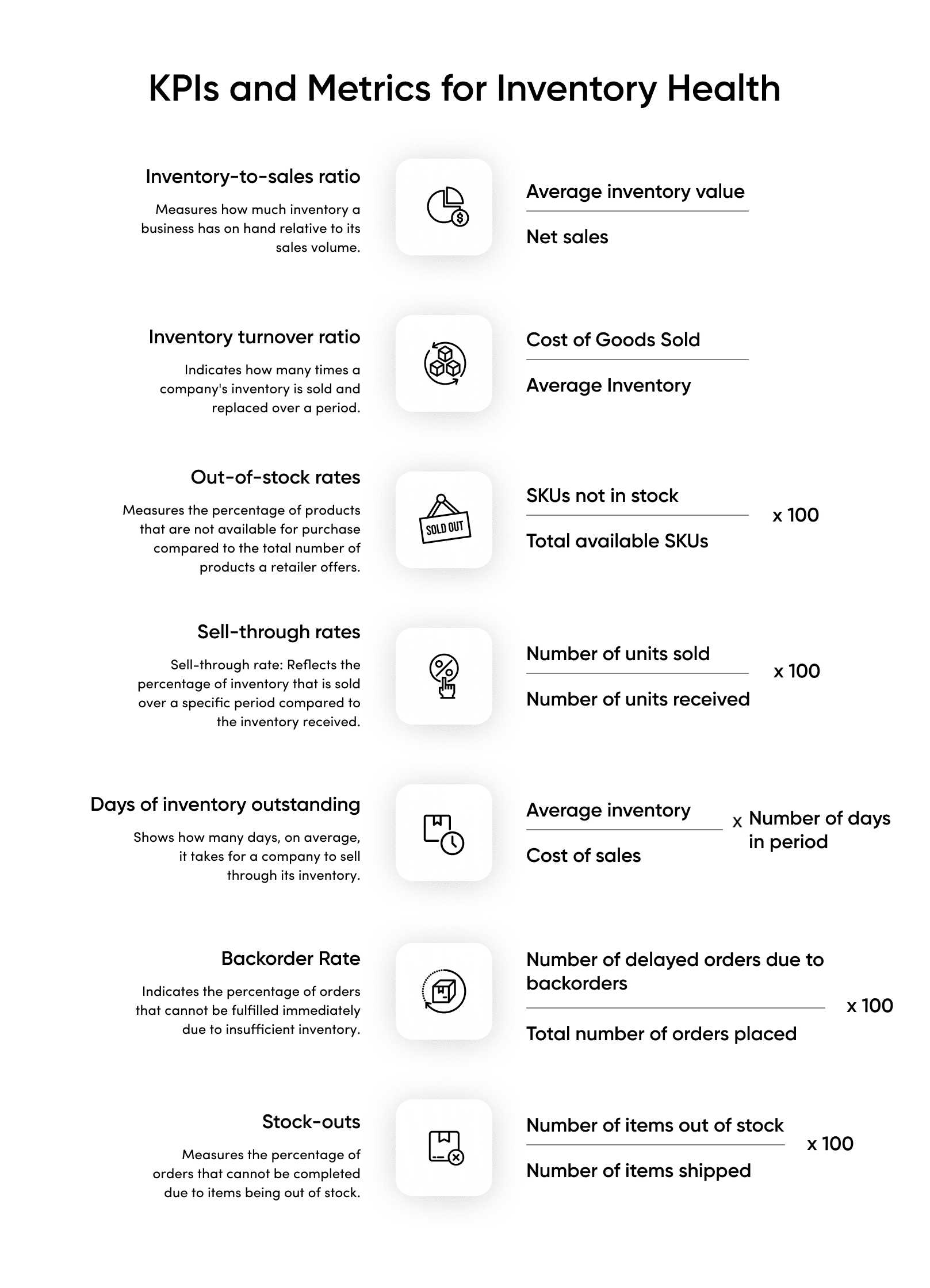

Important retail KPIs and metrics to assess include the inventory-to-sales ratio, inventory turnover ratio, out-of-stock rates, sell-through rates, and more.

From markdowns and promotions, to dropshipping, to pre-orders and backorders, there are several key strategies that retailers can implement to improve their inventory health.

fabric’s composable commerce services gives retailers the tools they need to optimize inventory health and build enterprise-ready commerce experiences on any channel.

“Inventory is fundamentally evil. You kind of want to manage it like you’re in the dairy business. If it gets past its freshness date, you have a problem.”

Tim Cook, CEO at Apple

For retailers, improving inventory health sounds simple enough. The balancing act involves optimizing stock levels to meet customer demand while efficiently managing costs.

But in practice, managing inventory is much more complicated and difficult to get right. For example, understock is when you don’t have enough stock to meet demand. It can lead to a whole host of problems, namely excessive backorders, cancellations, unhappy customers, and hidden costs like higher customer support expenses, escalations, and the need to offer customer appeasement coupons.

On the other hand, when you have too much stock, you’re stuck with capital tied up in inventory. Overstock not only impacts cash flows, it often translates to higher warehousing costs and operational costs, and potentially builds up dead stock that you may need to liquidate or write off at a financial loss. Markdowns and sales are often used to offload slow-moving inventory, but they can also impact retail margins and profitability.

To better manage inventory, retailers often turn to modern software for help. Inventory management systems, dropshipping, and pricing and promotions engines go a long way in achieving greater visibility and control over inventory systems.

Additionally, retailers can implement key strategies to better optimize stock levels and meet customer demand. In this article, we’ll go over some of the important things to look for when analyzing inventory in a retail business and present a blueprint for diagnosing and improving inventory health. Let’s dive in!

[toc-embed headline=”What is inventory health?”]

What is inventory health?

In retail, inventory health is about maintaining the right balance between stock levels, customer demand, and operational costs. In order for inventory to be healthy, it needs to ensure that products are available to meet customer demand without stockouts or excessive overstock.

In general, retailers want to optimize inventory levels to:

- Reduce website bounce rates, cart abandonment, order cancellations, and backorders

- Better manage overstock inventory

- Avoid aged inventory

- Reduce storage costs and optimize storage and restock limits

They can use a variety of metrics across sales, stock levels, and shipments to help forecast demand and make informed decisions about repricing, advertising, or removals. A few key performance indicators (KPIs) and metrics to assess include the inventory-to-sales ratio, inventory turnover ratio, out-of-stock rates, sell-through rates, days of inventory outstanding (DIO), backorder rate, and stockouts.

Diagnosing inventory health

Here’s are a few ways to diagnose your business’ inventory health:

- Conduct regular inventory audits for accuracy and to identify issues.

- Analyze historical sales data to spot demand patterns and forecast future needs.

- Use inventory management software to track stock levels, sales trends, and reorder points.

- Monitor key performance indicators (KPIs).

- Implement ABC analysis to categorize inventory according to value and prioritize management efforts. ABC analysis categorizes inventory items based on their value or importance to the business.

- Track and analyze supplier performance to identify issues.

- Assess warehouse operations to optimize space, storage, and pick, pack, and ship processes.

[toc-embed headline=”What are the key benefits of diagnosing and improving inventory health?”]

What are the key benefits of diagnosing and improving inventory health?

Inventory management can be used as a competitive advantage in retail. By diagnosing and improving inventory health, businesses can unlock a host of benefits that go far beyond streamlining operations. Here are some key advantages for optimizing inventory levels.

Lower costs

By diagnosing and improving inventory health, retailers can prevent overstock situations where excess inventory remains unsold. Reducing surplus stock helps retailers to lower holding and storage costs in warehouses, DCs, and retail stores, and lowers the risk of accumulating dead stock that must be disposed of or sold at a loss.

Optimized storage space

Optimized storage space ensures efficient utilization of warehouse or retail floor space, reducing storage costs and maximizing capacity for new inventory. Retailers should strive to minimize wasted space and organize inventory strategically.

Reduction of aging inventory

Aging inventory devalues over time. To improve profitability in the product lifecycle, it’s important to sell inventory while the items are still marketable and desirable to customers. Retailers also want to minimize outdated or unsellable inventory. By optimizing stock levels across the product lifecycle, businesses lower the risks of inventory becoming obsolete.

Improved cash flow

Healthy inventory optimizes the flow of cash by reducing the amount of capital tied-up in excess inventory. Freeing up cash flow allows retailers to allocate more capital to other areas of the business.

Enhanced customer satisfaction

Stockouts can lead to disappointed customers. Optimal stock availability ensures that customers can find the items they want when they want them. This enhances customer satisfaction and builds brand loyalty, leading to repeat business and higher customer lifetime value (LTV).

[toc-embed headline=”7 strategies to improve inventory health for retailers “]

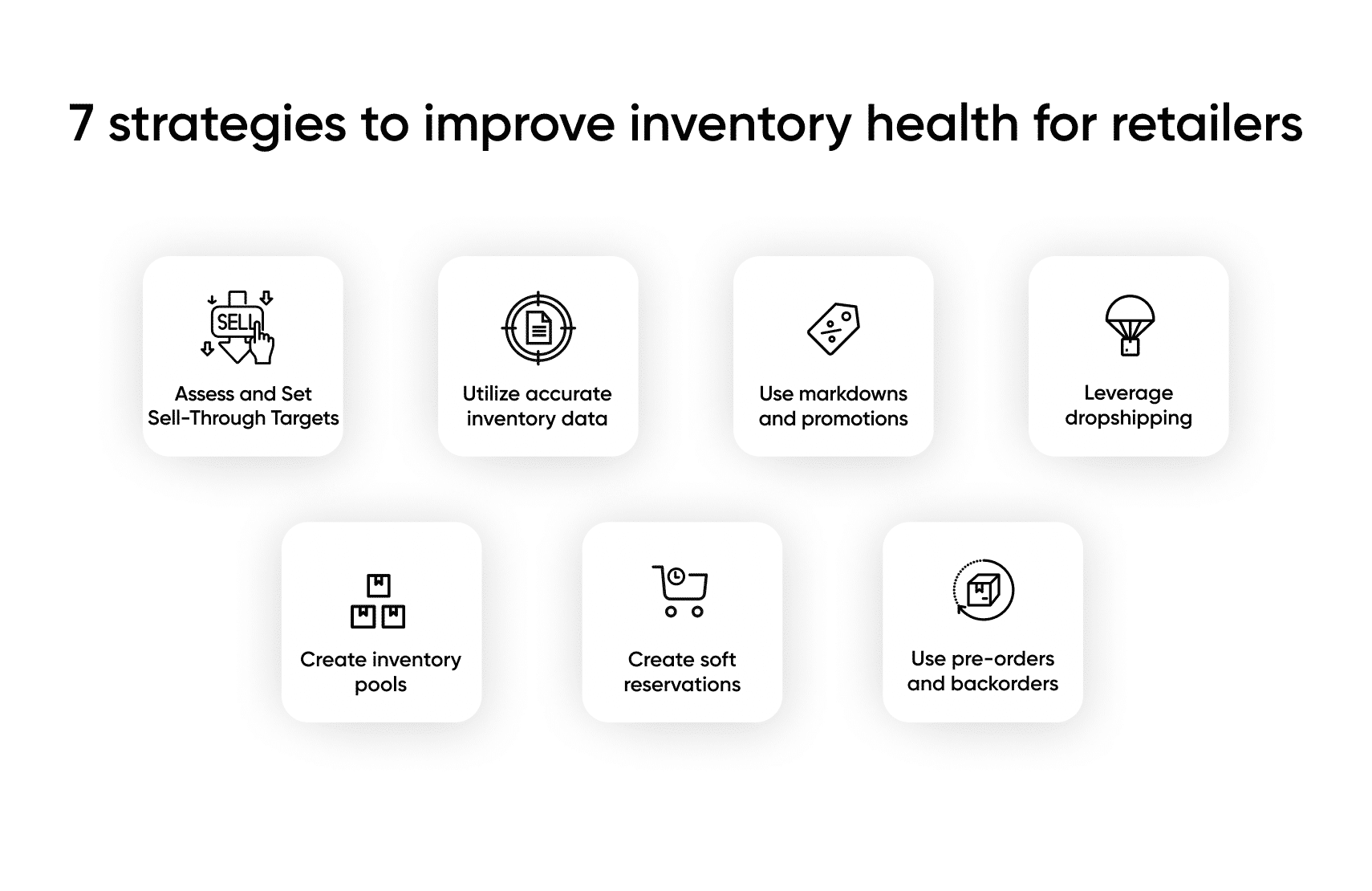

7 strategies to improve inventory health for retailers

The benefits of having healthy inventory levels extend beyond more efficient operations. It can improve a business’ overall financial health, enhance customer relationships, and increase competitiveness in the market.

For retailers seeking to enhance their inventory health, we’ve compiled a list of strategies that can help optimize stock levels, reduce costs, and improve business performance. Here are 7 must-know strategies that retailers can adopt.

1. Assess sell-through rates and set monthly, quarterly, and yearly sell-through targets

Sell-through rate measures the amount of inventory sold as a percentage of the amount of inventory received within a specific time frame. This metric indicates how efficiently products are moving off the shelves. Monthly sell-through rates of 80% and above are considered good for retailers.

Assessing historical sell-through data can reveal trends and patterns in demand that can inform a business’ inventory management decisions. Retailers can set monthly, quarterly, and yearly sell-through targets for products and categories, which will help guide resource allocation and inventory planning, especially with setting accurate and specific reorder points to replenish stock when needed.

2. Utilize accurate inventory data

Forecasting demand and planning corresponding inventory levels can only be done with accurate inventory data. A robust order management system (OMS) like fabric OMS can accurately sync inventory across all sales channels, warehouses, and retail locations, giving retailers a real-time, 360-degree view of inventory availability across the network. Retailers can use accurate data to anticipate future demand and adjust levels accordingly, preventing stockouts during peak periods and avoiding overstocking during slow periods.

3. Use markdowns and promotions

By analyzing sales data, retailers can identify slow-moving or seasonal items that may benefit from markdowns and promotions. With a real-time pricing and promotions engine like fabric Offers, retailers can set up price and promotion rules and use price reductions, promotional campaigns, discount stacking, and coupons to clear excess inventory and stimulate demand. Its powerful capabilities also allow you to narrowly target unhealthy inventory using a mix of product categories, collections, or attributes.

However, it’s important to keep your margins goals in mind when using markdown management across categories. Lower margin items may be sold at a loss (known as “loss-leaders”) if they’re bundled with higher margin products to offset initial losses.

4. Leverage dropshipping

Dropshipping is a fulfillment strategy that allows retailers to sell products without carrying stock. Businesses can use a dropshipping platform like fabric Dropship to connect with quality dropship suppliers to expand product offerings, test products and categories, fulfill orders directly to customers, backfill orders to avoid out of stock situations, and reduce the need for stocking and warehousing inventory.

5. Create inventory pools

With a modern OMS, retailers can use inventory segmentation to categorize inventory by attributes, locate items, and create inventory pools of products or inventory networks to control the availability of stock to sell in each channel, market, or region. This allows businesses to plan warehousing and fulfillment locations based on the physical proximity to customer demand. Retailers can minimize lead times, reduce transportation costs, and quickly fulfill orders to meet customer expectations.

6. Create soft reservations

With robust cart and checkout functionality, retailers can create what’s known as soft reservations of stock for customers. When inventory is running low, you can reserve units for people that are showing active interest in shopping, which helps to prevent out of stock issues. This strategy only works with real-time visibility and live inventory checks in carts, but it is used as a prevention mechanism to avoid order cancellations and cart abandonment.

7. Use pre-orders and backorders

In an OMS, pre-orders and backorders engines can help retailers plan for the amount of inventory required to meet customer expectations. For example, pre-orders generate anticipation and allow businesses to manage inventory for upcoming product launches. By allowing customers to reserve items before they are available, businesses can gauge demand, reduce financial risk, and ensure inventory levels align with expected sales. This not only builds excitement but also helps with inventory planning as well.

Similarly, backorders enable businesses to fulfill orders despite stockouts, providing insights into inventory needs while maintaining customer satisfaction. However, effective communication of revised delivery estimates is crucial for managing expectations and preserving positive customer relationships.

[toc-embed headline=”fabric can enhance inventory health for retailers”]

fabric can enhance inventory health for retailers

Implementing these seven strategies can help retailers improve their inventory health. From data-driven decision-making to markdowns and promotions, each strategy plays a crucial role in maintaining optimal stock levels to meet demand.

fabric’s composable commerce services, with native OMS, dropshipping, pricing, promotions, and cart and checkout, gives retailers the tools they need to optimize inventory health and build enterprise-ready commerce experiences on any channel.

If you want to learn more, or if you’d like to experience how our platform can modernize commerce, schedule a demo with our team here.

Digital content editorial team @ fabric