What are the Core Features of a 3PL Order Management System?

The global 3PL market is expected to reach $1,789.94 billion by 2027, making its 3PL order management system a worthwhile e-commerce practice.

Core 3PL order management system must address unique supply chain issues like shipping, inventory tracking, SKU system, and reverse logistics.

Using updated technology tools and software like OMS and WMS can help streamline logistics and reduce bottlenecks across the supply chain.

fabric OMS lets brands and retailers effectively build real-time connections with third-party logistics providers.

The e-commerce landscape has taken a massive shift from its condition years ago. While new companies are settling and taking advantage of digital sales, the competition is fierce, and it’s never been more challenging to grow an e-commerce brand efficiently. Both startups and established brands now focus on their core competencies, outsourcing fulfillment and business-related logistics to third-party logistics partners (3PLs).

3PL order management lets small businesses outsource labor and cost-intensive operations to vendors with more resources and well-developed infrastructure. Doing this not only improves a brand’s order fulfillment and customer loyalty but also helps with supply chain management, eliminating issues like labor shortages, port congestion, and expensive freight and last-mile carrier cost.

The global 3PL market was estimated at $1,027.71 billion in 2019 and is projected to top $1,789.94 billion by 2027. 3PL brands continue to see a leap in their transit time worldwide, with FedEx having an average transit time of 4.34 days at the end of the 2021 holiday peak season. Moreso, 70% of brands will add new sales channels in 2022, which means more transit times for 3PL vendors.

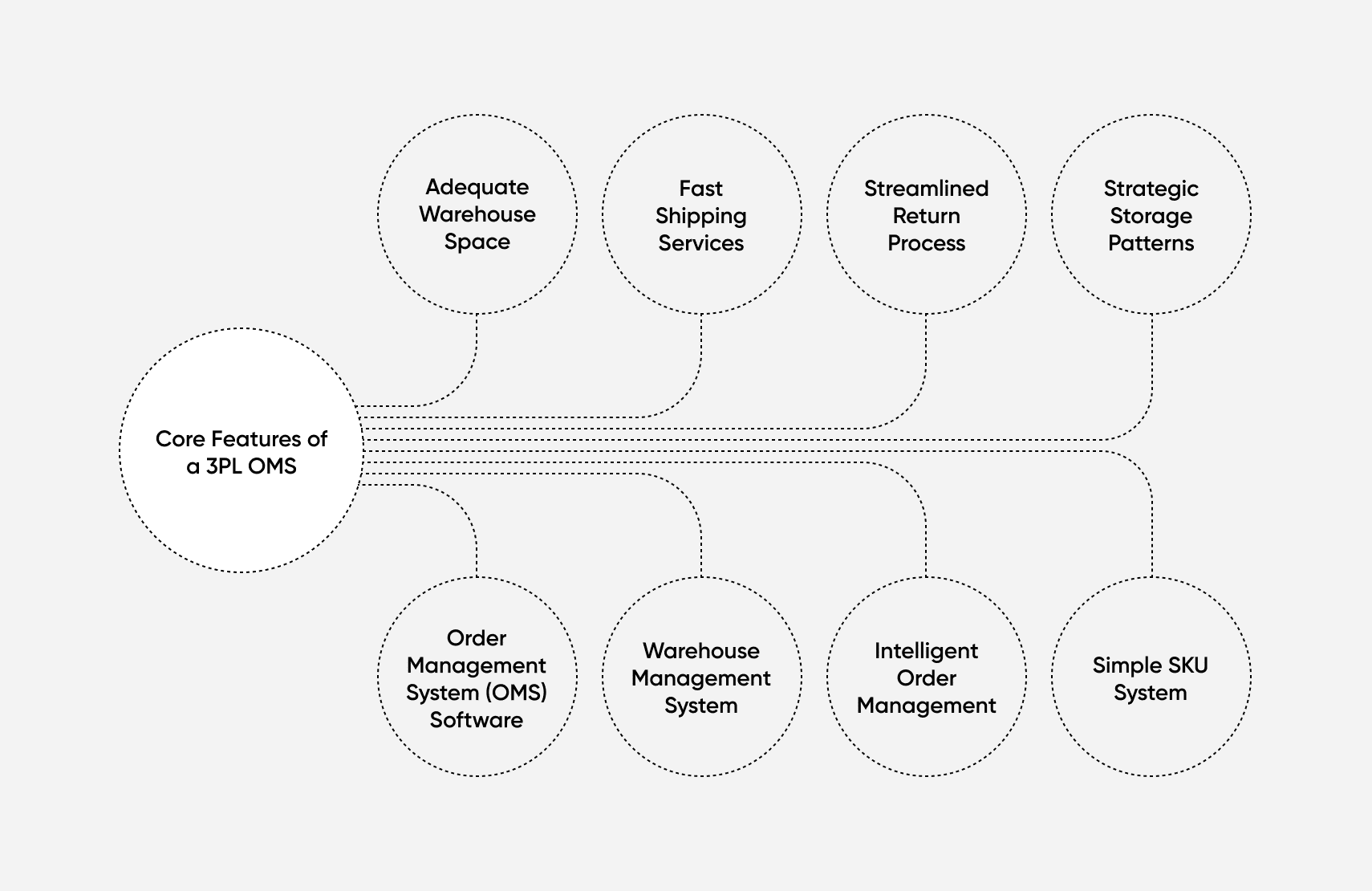

While the 3PL order management system helps to streamline logistics, to take advantage of this concept effectively, retailers need to examine the core features, which includes:

- Adequate warehouse space

- Fast shipping services

- Streamlined return process

- Strategic storage patterns

- Simple SKU system

- Intelligent order management

- Warehouse management system

- Order management system

Let’s dive into each feature to help merchants maximize the benefits of the 3PL order management system.

[toc-embed headline=”Core Features of a 3PL Order Management System”]

Core Features of a 3PL Order Management System

Adequate warehouse space

Scaling an e-commerce store comes with growing demands, resulting in more orders coming your way. For a brand that runs internal warehousing, the surge in orders due to seasonal changes or increased customer base can quickly lead to more product sourcing beyond the warehouse capabilities.

If the brand’s 3PL partner is not well-equipped or lacks adequate warehouse space to accommodate inventories, it can hurt its loyalty and reputation, leading to reduced revenue and customers. Thus, considering the available warehouse space of potential 3PL partners is a core requirement for an effective 3PL order management system.

Fast shipping services

As e-commerce grows into global adoption, consumer expectations about shipping speed, delivery time, and associated costs are changing. 69% of consumers may not shop with a merchant in the future if ordered items don’t arrive within two days of the date promised. Big players like Amazon and eBay now use 2-day deliveries and free 3-day shipping initiatives to attract customers.

3PL companies must have critical technology systems and operational processes to ensure accurate orders are shippable at scale, especially during peak season or order times. It’s also crucial that retailers choose 3PLs based on proximity to their customers. This helps to streamline logistics and ensure urgent orders get to their destination fast.

Streamlined return process

Reverse logistics is an essential part of running an e-commerce store. Beyond getting an order picked, packed, and shipped in as little time as possible, merchants must ensure a streamlined return process to encourage repeat purchases and boost revenue.

Whether someone orders an item by mistake or the product gets damaged during shipping, brands should partner with experienced 3PL vendors who have a streamlined process to receive and document the receipt of products while also following established business rules for returned orders.

Strategic storage patterns

In the 3PL order management system, inventory management and storage techniques determine the speed at which 3PL providers get products to the customer’s destination. Strategic inventory storage procedures can increase efficiency and help 3PL warehouses save time and money during the picking and packing process.

Operators should have an approach in place for segmenting fast-moving and date-sensitive products differently while adhering to various regulatory and safety measures. Regular physical audits of inventories are also an excellent way to ensure that the physical count of inventory aligns with what is in the system.

Simple SKU system

Partnering with 3PLs also aims to ensure accurate stock taking and inventory tracking. Essentially, this comes down to conducting stock counts while storing each unique SKU in its own bin or shelf space to optimize the picking lists and make order fulfillment as efficient as possible. Retailers must use simple SKU patterns to improve sorting and delivery.

Intelligent order management

Nothing is more frustrating in e-commerce than having a 3PL company that is hard to reach. In most cases, this is due to a lack of workforce and needed technology stacks. 3PL providers can go a step further by equipping their team with intelligent order management, accurately monitoring inventory and providing real-time reports, as well as ensuring end-to-end visibility across the supply chain.

Warehouse management system

Warehouse management system (WMS) lets 3PLs manage daily warehouse tasks and define processes for picking, packing, and shipping. 3PLs manage the receiving process by tracking incoming deliveries and then updating inventory. The 3PL provider’s WMS can do this automatically at the end of each day.

A good 3PL should integrate warehouse management software to simplify the inventory receiving and storing process. The software will identify where a product is stored and when it was placed in storage to make it easy to fulfill and decide what to fulfill once an order comes in.

Order management system software

A standalone order management system (OMS) software gives you a flexible solution for creating a real-time connection with logistics providers. Some OMS can store return rules for items, including 3PL stock.

These rules determine how long a customer has to initiate a return from their account. An OMS also ensures order completeness and accuracy, ensuring both retailers and 3PL providers have the correct address to eliminate frictions and delays when fulfilling orders.

Tech advocate and writer @ fabric.