Introducing Next-Gen Fulfillment Orchestration for E-Commerce

Packed with new functions and capabilities, fabric’s latest OMS update features distributed order management (DOM) and advanced order routing to further streamline order fulfillment for mid-market and enterprise customers. Here’s a quick preview of what’s to come from our biggest and most powerful product release yet.

When it comes to the high stakes world of enterprise-level software-as-a-service (SaaS), some of the most exciting and innovative work being done is in the rapidly-evolving area of order management.

Over the last several months, our teams have been hard at work rebuilding our industry-leading order management system (OMS) application from the ground up, leaving no stone unturned and no solution untested, to deliver even greater features and benefits to our customers.

Now we’re poised to kick our latest plan into high gear.

With fabric’s upcoming OMS update, our API-first, cloud-native, and modular application is about to get even better. From distributed order management (DOM) and advanced order routing, to network aggregation and preorder/backorder inventory management, we’re delivering some of the most advanced fulfillment orchestration technologies to the market.

In fact, we’re set to release over 50 incremental features that will help businesses dramatically strengthen their inventory accuracy and availability, improve order fulfillment, and simplify omnichannel order processing. Not only will these enhancements help companies reduce out-of-stock (OOS) rates and decrease processing times, but they’ll also help to lower costs across the entire order lifecycle, which will ultimately lead to better conversions and repeat purchases for products and services.

[toc-embed headline=”What’s New with fabric’s Big OMS Update?”]

What’s New with fabric’s Big OMS Update?

Unlike the vast majority of the solutions found in the market, fabric’s original OMS application was developed specifically for mid-market and enterprise retail. From its sleek and simple user interface (UI) designed for faster onboarding, to its cloud-native and microservices-based architecture engineered for maximum efficiency, speed, scale, and flexibility, the application gave modern retailers exceptional control over all aspects of order fulfillment operations.

But we wanted to make our system even better.

Over the last few months, we seized the opportunity to double down on the mid- and enterprise markets by completely rebuilding our application from scratch. With new state-of-the-art, multitenant cloud architecture built on Amazon Web Services (AWS), our software has become more powerful, flexible, and cost-effective than ever before.

For example, we deliver over-the-air software updates that provide new features and functions to all our customers. This model is in stark contrast to outdated single-tenant architecture where customers must contend with vendor lock-in and are charged exorbitant prices for minimal upgrades. In addition, the system is completely decoupled from all other fabric platform products for maximum flexibility and it boasts multiple modular applications rather than a monolithic application.

With these critical architecture and infrastructure pieces in place, our teams were given the freedom to transform fabric OMS from a competitive application into a dominant enterprise-ready app—complete with the latest and most exciting features and capabilities, which are all made available out-of-the-box.

However, some of the biggest upgrades are also the most powerful. These include major enhancements to DOM and advanced order routing, network aggregation, preorder/backorder inventory management, and contact center support, to name a few.

[toc-embed headline=”DOM and Advanced Order Routing”]

DOM and Advanced Order Routing

Perhaps the biggest update we’re rolling out for customers is advanced distributed order fulfillment capabilities.

Traditionally, order management software does a great job of orchestrating the life cycle of orders, starting from order creation and leading to fulfillment, billing, shipping, and financial posting. Software can also manage the post order creation and delivery life cycle of an order such as cancellation, updates, and return management as well.

But where legacy software falls short is with larger and more complex e-commerce operations.

For instance, companies that have large fulfillment requirements and many sales channels (i.e. omnichannel, multi-channel, multi-brand, global footprint, and complex fulfillment operations) require much more robust solutions that can not only manage inventory from a variety of different locations but also handle giant order volumes. That’s where DOM comes in.

fabric’s new OMS update is built for mass scalability to support modern distributed commerce models, including newer buy-online-pickup-in-store (BOPIS), ship-to-store (for store pick up or replenishment), and store fulfillment (as mini distribution centers) models. For example, advanced order-routing and logic-based rules can drastically simplify the fulfillment process by determining the optimal fulfillment locations to ship orders from.

Whether products are located in distribution centers, plants, stock locations, or 3PLs, our innovative solutions are primed to ensure that orders are delivered within set times, costs, and other parameters. Features like conditional sourcing can specify conditional rules in the UI to automate sourcing decisions, and rank-based sourcing can specify if orders should be delivered by the closest or highest-ranking facility that is first in stock. Meanwhile, input for fulfillment logic can be pulled from a variety of sources, including inventory data, product data, order data, and facility data as well.

And what happens if a given location can’t fulfill an order? Our order “bounce” reallocation feature accepts no-fulfill notifications from the warehouse or store system, then automatically re-allocates the order to a location that’s eligible to source the order from.

These are just a few of the many new DOM features that will help brands leverage stock across multiple locations, reduce shipping costs, optimize inventory levels, reduce overstock, and boost inventory velocity. Intelligent order routing will not only lower OOS rates and reduce costs, but it’ll also help improve profitability for businesses by delivering best-in-class fulfillment experiences to customers.

[toc-embed headline=”Network Aggregation”]

Network Aggregation

Another exciting feature fabric is rolling out is network aggregation.

When it comes to large companies that must manage multiple buildings, warehouses, and stores, legacy inventory management systems have no concept of the availability of products across the network. This lack of visibility leads to errors and delays, which causes ripple effects across the order fulfillment life cycle.

But as part of offering a more robust inventory data model, fabric OMS can pre-aggregate network rule sets so that when storefronts operate, they know exactly what’s available at all times. For example, a store will know whether an order is constrained by geography or fulfillment location, or whether the order requires in-store pickup, online delivery, or another fulfillment method.

To enhance visibility, network aggregation creates pools of inventory across multiple locations by specifying product and location attributes as aggregation criteria in the UI. Storefronts can then pass the network ID in the inventory API request and obtain the inventory level for the entire network in the response.

The importance of having highly robust enterprise inventory visibility cannot be understated. Beyond network aggregation, fabric is also releasing improved inventory tracking, inventory event notifications, custom inventory attributes, and visibility into local availability, available-to-promise inventory, and segment inventory as part of our new OMS update.

[toc-embed headline=”Pre-Order and Backorder Inventory Availability”]

Pre-Order and Backorder Inventory Availability

Two important pieces of our OMS that are getting a significant upgrade with this release are fabric’s pre-order and backorder engines.

Giving customers the ability to pre-order products and secure them before they’re released is not only a great way to forecast demand and prepare inventory for an upcoming launch, but it is also a great tool for businesses to build anticipation for product releases.

Available-to-promise (ATP) refers to the projected amount of inventory a business has in stock that’s ready to sell and not allocated for existing customer orders. ATP helps businesses keep enough inventory available to be sold, but also anticipates future requirements using data-based forecasts. With our enhanced pre-order capabilities, customers have the ability to sell items before they are ATP and release them on the specified pre-order release date that they become ATP.

Backorder capabilities have also been upgraded significantly. With our latest update, businesses can designate eligible inventory that is permitted to be sold when the products are not on hand. Our enhanced engine will automatically convert orders to backorders and then release them from the backorder designation as soon as inventory becomes available. Orders can be further controlled by limiting the number of backorders to the quantity set by the merchant.

[toc-embed headline=”Contact Center Support”]

Contact Center Support

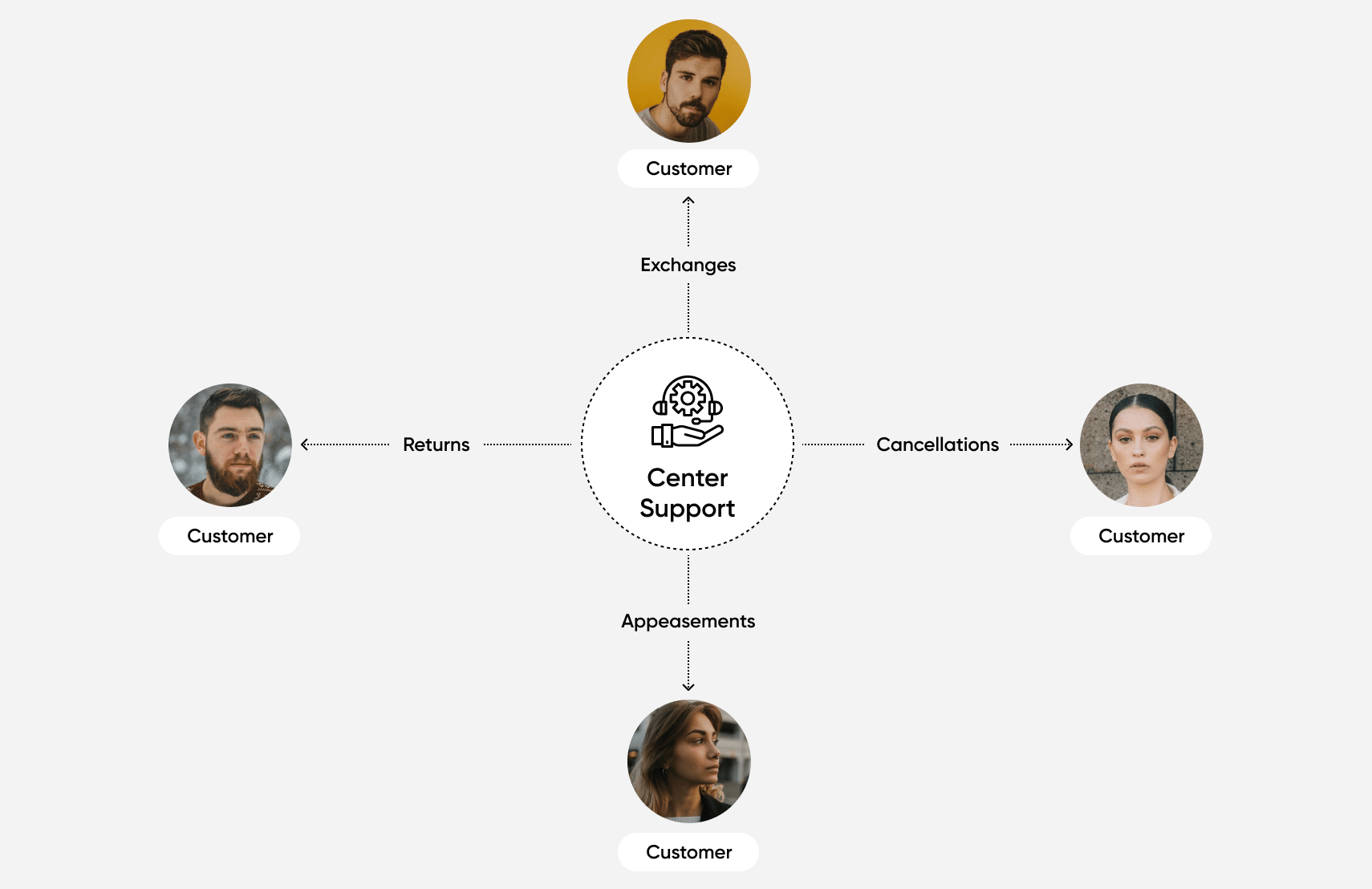

Another major part of our rollout includes a slew of enhancements for contact center support. Early on, we recognized that mid-market and enterprise businesses required robust contact center capabilities, and with our newest release, we’re excited to bring some important updates to our customers.

For instance, the order edits function now allows companies to make changes to the ship-to address or update the values of custom attributes in the order for value-add services and notes. And for better tracking and to improve the customer service experience, companies can update orders with employee IDs so they can compile a record of services performed by each customer service representative (CSR).

The order audit trail function allows companies to audit every update to the order record, including all manual interventions during the order life cycle process. Meanwhile, appeasements allow for partial refunds to the customer for any customer service issues. These can arise from a discount not being applied or if a purchase experience is unsatisfactory.

Our latest update also simplifies exchanges and the reshipping of products as well. If items are not received, companies can update orders to place a new line item for allocation at no additional cost. And for peace of mind, businesses also have the ability to configure abuse prevention policies in the UI.

And that’s not to mention the host of additional features that will help boost the productivity of contact centers. From automated refunds to cancellation reason codes for categorizing cancellations, fabric is delivering powerful tools and capabilities that will go a long way in setting up contact centers for long-term operational success.

[toc-embed headline=”fabric OMS Takes Order Management to the Next Level”]

fabric OMS Takes Order Management to the Next Level

With our latest OMS update, fabric has never been more mid-market and enterprise-ready. We’re delivering modular and scalable order orchestration software that’s purpose-built for retail, which will help businesses provide superior fulfillment experiences to their customers.

Best of all, companies will get more for less with their IT and business teams. Not only will operators gain unprecedented control of their commerce platform and modules (with lower costs and less operational overhead), but they’ll also be able to stand up and update order fulfillment logic without writing code, which will drastically reduce the need for developer resources.

With all the new features in this release, merchants can consolidate their order lifecycle to a single interface from legacy systems, orchestrate new fulfillment experiences for customers, reduce OOS rates, and free up engineering resources to focus on what they do best. Furthermore, this will allow digital commerce teams to optimize digital experiences, fulfillment operations teams to optimize logistics, and customer service teams to focus on servicing orders.

With fabric OMS, order management will never be the same again. You can learn more about its upgraded features and functions here.

Director of Product Management @ fabric. Previously Digital Product Manager @ Bed, Bath, & Beyond.