How Can Inventory and Order Management Software Work Together?

Organizing inventory properly lets you meet ongoing customer expectations, ensuring an effective order fulfillment process.

Order management and inventory management combine to help companies continuously provide a great customer experience.

Without a global view of all inventory across the entire fulfillment network, it’s difficult to optimize inventory across channels.

Cloud-based order management systems like fabric OMS provide a central hub that gives retailers a global view of all available inventory.

Inventory management is a fundamental building block that empowers brands and retailers to provide streamlined, fast, and effective order fulfillment to win customer loyalty. When your inventory is properly organized, the entire supply chain is on the right track to deliver the right goods to the right people at the right time.

With a cloud-based order management system, order and inventory management software can work together. This makes it easier to keep accurate records of inventory throughout the supply chains. According to Software Path, 43% of small businesses still use a manual process to track their inventory. The same study also found that businesses using inventory management software had 95% inventory accuracy.

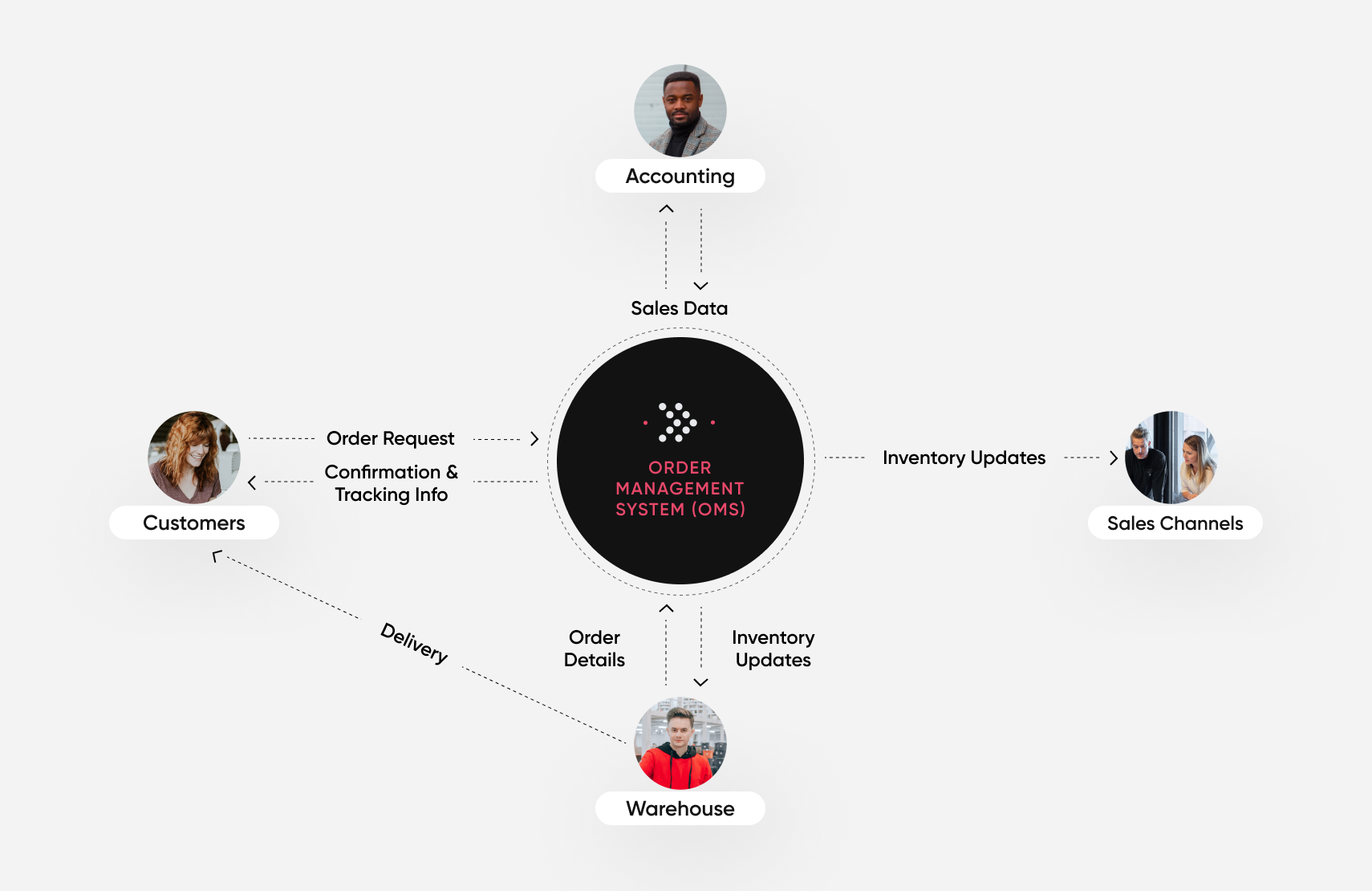

By investing in an order management system (OMS), you’ll be able to sync information across sales channels to ensure inventory levels are accurate at all times. Furthermore, you can reduce the capital cost of carrying excess inventory, deliver an excellent customer experience, and ultimately, generate more sales for your e-commerce business.

[toc-embed headline=”Relationship Between Inventory and Order Management”]

Relationship Between Inventory and Order Management

Inventory management is the process of ordering and tracking stock as it arrives at the warehouse, controlling and overseeing purchases, and maintaining the storage of stock. Order management is responsible for receiving, managing, and tracking orders, ensuring smooth and speedy deliveries. Both help companies meet customer expectations and turn one-time buyers into repeat customers since 38% of online shoppers will abandon their orders if it will take more than 7 days to arrive.

Once a customer places an order, inventory levels are updated across platforms. Inventory is allocated to that specific order, and status is changed in the inventory to put it “on hold” for that order. Most companies often leverage OMS to combine both tasks, giving them a global view of the entire order fulfillment process. Furthermore, with both systems integrated, the OMS can recommend which location should fulfill the order, eliminating multiple shipments for a single order and ensuring the quickest delivery.

[toc-embed headline=”Managing Global Inventory”]

Managing Global Inventory

When inventory is siloed across channels such as stores, distribution centers, or in a partner’s locations, knowing where inventory is and tracking changes in real-time—including in-transit inventory—is challenging.

This is even tougher for brands and retailers that use multiple channels. Without a general idea of the inventory available in stock, retailers might say “no” instead of “yes” and utilize stock that is held in-store to fulfill customers’ orders.

Providing optimized fulfillment to meet today’s buyer’s expectations demands that inventories across the web, retail, or wholesale channels be managed from a single place. This requires a global view of all available inventory across the entire fulfillment network. Let’s look at two key ways to optimize inventory across channels:

Just-in-time fulfillment

Just in time fulfillment allows merchants to grow their product catalog without investing excessively in inventory or warehouse. With this process, you place your orders with suppliers only when a customer places an order with you.

For example, you’d list an item for sale on your own website or another marketplace like Amazon. When a customer purchases that item, you quickly place your order from the supplier. Unlike drop shipping, the items are not delivered directly to the customer. Rather, they are delivered first to you for repackaging before being shipped to the customers. This strategy is effective because:

- You don’t need a bigger store to process a large amount of inventory

- It requires lower capital investment since there’s no need for bulk inventory purchase

- It ensures that customers receive their product

- Retailers can easily expand product offerings since inventory isn’t needed

Inventory and order management software such as an OMS gives a global view of all operations and makes it easier to see when someone places an order, so you can contact the necessary suppliers and deliver “just in time.”

Review aged inventory

If you have an excess or wrong mix of inventory, reviewing aged inventory is a critical way to optimize your inventory. This is because eliminating old inventory helps to reduce inventory holding costs that may accumulate as a result of having a lot of warehouses to pay for.

During the process, you label any inventory that has been in stock for 90 days as old or aged inventory and should be either replaced or sorted to be used in areas where they’re needed most. To make this more effective, monitor the total on-hand inventory over 90 days as well as the percentage of inventory over 90 days.

[toc-embed headline=”Migrate to a Cloud-Based Order Management Platform”]

Migrate to a Cloud-Based Order Management Platform

The retail inventory management software market is split between on-premise or cloud-based platforms. While the former proves effective to some extent, it’s expensive to manage and you risk losing important data if the system develops technical problems. It’s why Mazda moved their inventory to the cloud, boosting their performance by 70%.

As SKUs, channels, and distribution outlets proliferate, optimizing order management continuously depends on achieving an accurate and unified real-time view of inventory tracking and all inventory across the entire fulfillment network.

Cloud-based order management software has the real-time visibility that retailers need to optimize order management and fulfillment in every channel. Instead of a monolithic on-site solution, a headless setup is built using decoupled cloud-based platforms and microservices combining both inventory and order management in a single place.

Tech advocate and writer @ fabric.